How to stop a mechanical seal from leaking?

Stop pump mechanical seal leaks by shutting down, inspecting, replacing seals, and ensuring proper installation to prevent future leakage.

Acquire all kinds of knowledge from professional China Manufacturer

Stop pump mechanical seal leaks by shutting down, inspecting, replacing seals, and ensuring proper installation to prevent future leakage.

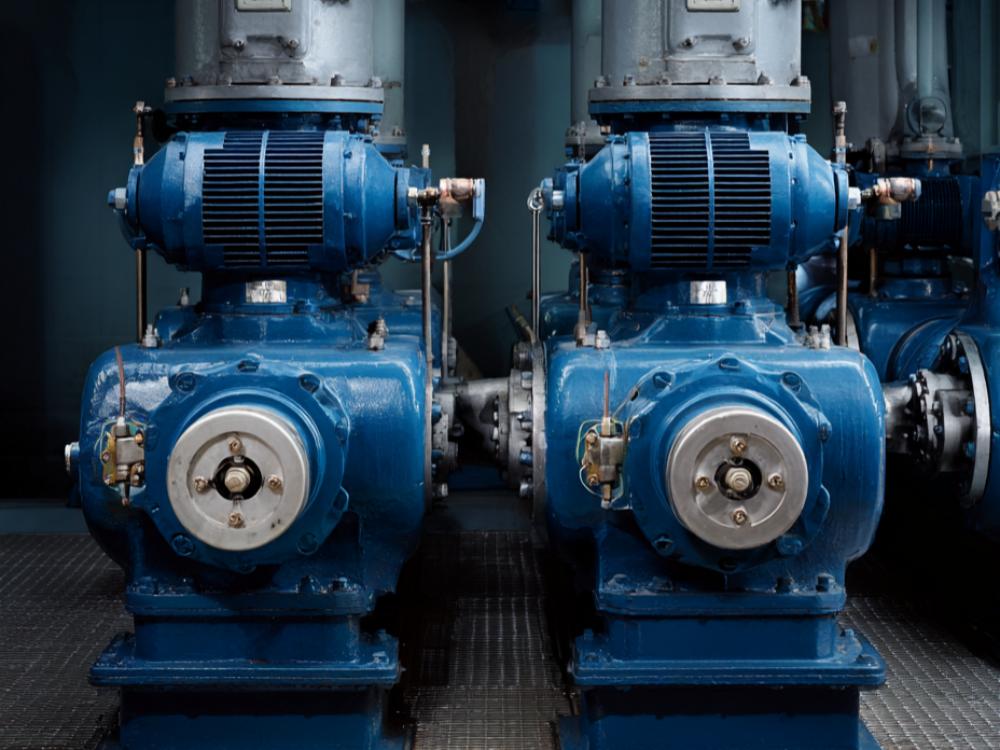

Mechanical seals for pumps include component, cartridge, split, gas, and balanced types. Each seal type suits different pump needs and operating conditions.

Double mechanical seals for pump systems are essential for hazardous, abrasive, or high-pressure fluids, ensuring safety, compliance, and leak prevention.

A mechanical seal for pump prevents water leaks at the shaft, boosts efficiency, and protects pump components for longer, reliable operation.

Cartridge seal offers easy, error-free installation, while component seals need assembly and skilled fitting. Compare reliability and maintenance costs.

Cartridge mechanical seals install as complete units, reducing errors, while non cartridge seals require assembly and skilled alignment.

Mechanical pump seals offer better reliability, less maintenance, and lower long-term costs than centrifugal pump packing for most applications.

Carbon and ceramic mechanical pump seals differ in wear resistance, chemical compatibility, and cost, impacting pump performance and maintenance needs.

A single mechanical seal pump uses two faces and a spring to prevent leaks, protect equipment, and ensure reliable, cost-effective operation.

Single mechanical seals are most commonly used as the centrifugal pump mechanical seal, offering reliable leak prevention for various pump applications.

Select the best mechanical seal on a pump by matching fluid type, pressure, temperature, and shaft size for leak prevention and equipment safety.

A pool pump shaft seal typically lasts 2-3 years with proper care. Regular maintenance and balanced water chemistry help extend its lifespan.

A pump shaft seal prevents liquid leaks where the shaft exits the pump housing, protecting pump efficiency, safety, and system reliability.

Single cartridge mechanical seal has one set of seal faces. It stops leaks around pump shaft seals. Double cartridge mechanical seal has two sets of seal faces. This gives better

You can ensure equipment safety and protect the environment by following the correct procedures for replacing water pump seals. Using high-quality, original equipment manufacturer (OEM) mechanical seals, such as VEEKTER

Sales

Hi, I am the author of this article, I have been in this industry for more than 20 years. If you want to wholesale pump seal, please feel free to ask me.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

About Victor

Contact Victor