When fixing a water pump seal, start by turning off the power and disconnecting the pump from the system. Remove the old seal and install a new cartridge mechanical seal to ensure reliable performance. Safety is crucial throughout the process, as leaks from a faulty water pump seal can lead to wasted water, contamination, and increased energy consumption. Victor Mechanical Seals offer effective solutions that comply with strict standards for clean water and are designed for easy installation. If a seal fails, costs can rise quickly due to lost production and additional repairs, especially when replacing an allweiler pump mechanical seal.

Key Takeaways

- Always turn off the power before you start repairs. Make sure the pump is not connected to power. This keeps you safe.

- Wear goggles and gloves to protect yourself from harm. These help keep you safe from injuries and dangerous fluids.

- Follow each step when you replace the mechanical seal. This helps stop leaks and makes sure it works right.

- Check the pump often for wear or leaks. This helps you find problems early and keeps the pump working well.

- Pick good seals, like Victor Mechanical Seals, for your pump. This can lower repair costs and make the pump work better.

Safety for Water Pump Seal

Power Off and Isolate Fluid

Safety is very important when fixing a water pump seal. Workers need to turn off the power before starting repairs. This stops the pump from turning on by accident. It also helps prevent electric shock. After that, workers should separate the pump from the fluid system. They must drain and depressurize the pump and pipes. This removes leftover pressure that could cause leaks or spills.

Tip: Always use lockout/tagout steps so the pump stays off during repairs.

Some common safety problems happen when replacing a seal. These include not putting the seal in right, broken gaskets, and parts that do not line up. These mistakes can make the pump leak and work less well. If bolts are loose or there is no lubrication, the seal can fail. Too much vibration and old bearings also make leaks more likely.

| Risk Type | Cause of Risk |

|---|---|

| Seal failure | Picking the wrong seal or using too much force when installing |

| Leakage of fluids | Skipping steps during installation can cause leaks right away |

| Damage to components | Parts that do not line up or pipe strain can break the mechanical seal |

| Environmental hazards | Leaks from bad seals can hurt the environment, especially with chemicals |

Use Protective Equipment

Personal protective equipment (PPE) keeps workers safe from injury and dangerous fluids. Safety goggles, gloves that resist chemicals, and special clothing are needed. Workers should make sure the area has fresh air so they do not breathe in bad gases or fumes.

- Put on safety goggles and chemical-resistant gloves.

- Wear special clothing to keep skin safe.

- Make sure emergency showers and eyewash stations are close.

- Use drip pans and absorbent pads to catch leaks.

- Throw away waste the way local rules say.

Checking the pump often helps find damage, wear, or leaks early. Training teaches workers how to stay safe. By following these safety steps, workers can stop accidents and protect themselves and the environment.

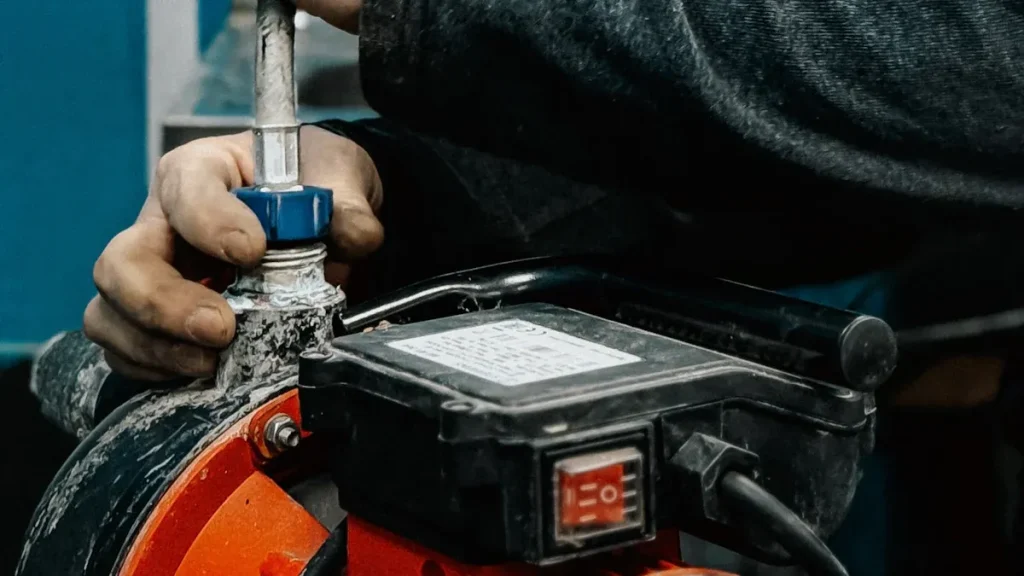

Replace Mechanical Seal

Replacing a mechanical seal in a water pump requires careful attention to detail. Each step helps prevent leaks and keeps the pump running smoothly. The following steps to replace mechanical seals will guide anyone through the process.

Disconnect Water Pump

- Turn off the power to the water pump.

- Unplug the pump from the electrical source.

- Close the inlet and outlet valves to isolate the pump from the system.

- Drain any remaining fluid from the pump casing.

Tip: Always check that the pump is fully isolated before starting work.

Remove Impeller

- Remove the bolts or fasteners holding the pump casing.

- Take off the pump cover to access the impeller.

- Use the correct tool to loosen and remove the impeller from the shaft.

- Set the impeller aside in a clean area.

The impeller sits in front of the mechanical seal. Removing it gives access to the seal for the next steps.

Take Out Old Seal

- Locate the mechanical seal behind the impeller.

- Carefully slide the rotary part of the seal off the shaft.

- Remove the stationary part from the seal chamber.

- Clean the shaft and seal chamber with a lint-free cloth.

Note: Avoid touching the sealing faces with bare hands. Dirt or oil can cause leaks after mechanical seal installation.

Install New Mechanical Seal

Victor Mechanical Seals are designed for easy installation and maintenance. The following steps show how to install a new seal:

- Check the new mechanical seal for the correct size. Measure the outside diameter, inside diameter, and width.

- Attach the rotating face to the shaft sleeve. Install the springs as shown in the manufacturer’s diagram.

- Slide the rotating component onto the shaft. Make sure it lines up with the stationary face.

- Secure the rotating part with set screws or a lock nut. Use the correct torque.

- Inspect and clean the gland plate. Replace O-rings or gaskets if needed.

- Position the gland plate over the seal components. Hand-tighten the bolts.

- Use a dial indicator to check alignment. Adjust bolts if necessary.

- Tighten the gland plate bolts in a crisscross pattern to the specified torque.

- Visually inspect all parts. Make sure the rotating component moves freely.

Tip: Do not run the seal dry. Fill the seal chamber with fluid before starting the pump.

Reassemble and Restart

- Place the impeller back onto the shaft.

- Reattach the pump cover and secure all bolts.

- Reconnect the pump to the system.

- Open the inlet and outlet valves.

- Restore power to the water pump.

- Prime the pump if needed, then start it and check for leaks.

Following these steps to replace mechanical seals helps prevent common mistakes. Using the wrong seal size, poor alignment, or over-tightening bolts can cause leaks or damage. Victor Mechanical Seals make mechanical seal installation simple and reliable for any water pump. Regular maintenance and careful installation extend the life of the seal and keep the system efficient.

Test Water Pump Seal

Check for Leaks

After installing a new mechanical seal, technicians should check for leaks before starting the pump. They can do this by visually inspecting the seal area and the support system while the pump is off. A small amount of moisture may appear at first, but a steady drip or puddle signals a problem. Most mechanical seals allow only a tiny amount of fluid to pass—usually less than 50 milliliters per hour for single seals. For hazardous fluids, the allowed rate is even lower and follows strict safety rules. If the seal passes this check, the technician can move to the next step.

Tip: Use a flashlight to look for drops or wet spots around the seal and gland plate.

Run and Inspect Pump

Technicians should run the pump and watch for any unusual sounds, vibrations, or heat. They should listen for smooth operation and check that the shaft rotates freely. During this time, they should also monitor the flow rate, pressure, and temperature. Comparing these numbers to normal values helps spot problems early. If the pump uses a dual seal with a support system, the technician should check the fluid level and make sure cooling water flows as it should. They should also inspect visual flow indicators and replace any dirty filters.

Recommended steps:

- Perform a pressure test to confirm no leaks under pressure.

- Rotate the shaft by hand to check for smooth movement.

- Watch the pump during startup for noise or vibration.

- Monitor the seal area for any signs of moisture.

Troubleshoot Issues

If a leak appears after installation, the technician should not panic. New seals sometimes leak a little at first. Running the pump through several heat and cool cycles may help the seal settle. If the leak continues, the technician should check if the seal was installed correctly. Air pockets in the system can also cause leaks, so bleeding the system may help. If problems remain, the technician should inspect the seal for damage or misalignment and review the installation steps.

Note: Always follow the manufacturer’s instructions for troubleshooting and maintenance.

Troubleshooting & Failure Analysis

Common Signs of Seal Failure

Technicians can find problems early by watching the water pump. They look for changes in how the pump works. Grooves or notches on the seal mean the pump had too much pressure. Squealing or popping sounds show there is not enough lubrication. If the wear tracks are uneven, the seal ring may be bent. Cracks or broken seal faces can happen from a hard hit or fast temperature change. A chipped or cracked seal ring can come from putting it in wrong. If black dust is around the seal, it usually means the seal did not get enough lubrication.

Tip: Check the pump often to find these signs before a big leak starts.

The table below shows common reasons for mechanical seal failure. It lists the symptoms and ways to stop them:

| Cause of Failure | Symptoms | Prevention Measures |

|---|---|---|

| Wear and Tear/Contamination | More leaks, damage you can see, pump works badly | Check and change seals; keep fluids clean |

| Improper Installation | Leaks, low pressure in the system | Use the right seal and size; follow the steps |

| Overheating/Dry Running | High heat, color changes, burning smell | Fill the pump first; watch the temperature |

| Shaft Misalignment | Vibration, noise, uneven wear | Make sure parts line up right |

| Shocks and Vibrations | Noise, shaking, broken parts | Build the pump well; check for vibration |

| Inadequate Maintenance | Slow leaks, pump works poorly | Check and replace seals often |

Identifying Root Causes

When a water pump has seal problems, technicians use different ways to find out why. First, they look for where the leak is coming from. They measure how much fluid has leaked out. They listen for odd sounds. They check how the pump is running and look for shaking. Technicians take vibration readings and look at old repair records. They see if the same problem happened before. They also check for past issues that could have caused the trouble now.

If the mechanical seal fails more than once, a closer look is needed. This helps find the real reason for the problem. When technicians know what caused it, they can fix it and stop it from happening again.

Note: Careful troubleshooting and failure checks help protect the pump and make the mechanical seal last longer.

Technicians can change water pump seals safely by following each step. This helps stop leaks from happening. Victor Mechanical Seals give strong sealing and last a long time. They also help save money on repairs. The table below lists their main benefits:

| Benefit | Description |

|---|---|

| Highly Effective Sealing | Better sealing means less chance of leaks. |

| Reduced Maintenance and Costs | Strong seals break less and cost less to fix. |

| Energy Conservation | The design lowers friction and saves energy. |

| Versatility | Works with many fluids and different pressures. |

| Reduced Wear on Components | Keeps pump parts safe and makes them last longer. |

People can buy Victor Mechanical Seals from trusted places:

- Official Victor Seals website

- Water Pump Seal

- Pump Mechanical Seal

- Mechanical Seal Ring

- Pump Spare Part

- Pump Seal

If someone is not sure what to do, they should ask a certified professional for help.