mechanical seal material

Mechanical seal material refers to the specialized substances used in the sealing faces, secondary sealing elements, and structural components of mechanical seals. The choice of material plays a decisive role in the performance, durability, and safety of pumps and rotating equipment.

Victor provides comprehensive material information to ensure you select the right seal for your application. For more information on material selection and application technical support, please contact Victor.

common pump seal material

Mechanical seal rings are the core components that determine sealing performance and service life. They are directly exposed to friction, pressure, and various operating media, which makes material choice a critical factor. The following are Victor provided ring materials in pump seals, each offering unique benefits to suit different working conditions.

Silicon Carbide Rings

Silicon carbide offers exceptional hardness, wear resistance, and thermal conductivity, suitable for abrasive or high-temperature fluids. It resists corrosion and maintains flatness under heavy load. Victor recommends silicon carbide faces for slurry pumps, high-pressure seawater pumps, and abrasive chemical services where long life and minimal maintenance are critical.

* For detailed ring parameters, please refer to the material specification table.

Carbon Rings

Carbon faces provide good conformability and low friction, reducing wear during startup and low-speed operation. They perform well with lubricated systems and tolerate slight shaft misalignment. Victor supplies carbon face seals for seawater pumps, fuel transfer units, and general-purpose industrial pumps that need reliable low-friction sealing and longevity.

* For detailed ring parameters, please refer to the material specification table.

Stainless Steel Rings

Stainless steel rings combine durability with cost efficiency. They provide good resistance to moderate corrosion and are widely used in general industrial pumps. Their strength and versatility make them a practical choice for standard applications.

* For detailed ring parameters, please refer to the material specification table.

Ceramic Rings

Ceramic faces offer excellent corrosion resistance and thermal stability, making them suitable for acidic or high-temperature fluids. They are hard but brittle, ideal for clean liquids and moderate abrasion. We use precision-ground ceramic faces in seals for chemical dosing pumps and cooling systems where corrosion resistance and dimensional stability are required.

* For detailed ring parameters, please refer to the material specification table.

Tungsten Carbide Rings

Tungsten carbide combines extreme hardness with excellent wear resistance and fracture toughness, suitable for heavy-duty, abrasive, and high-pressure services. It performs well in slurry pumps, mineral processing, and industrial pumping with solids. We offer TC faces for demanding marine and industrial pumps that require maximum durability.

* For detailed ring parameters, please refer to the material specification table.

mechanical seal material selection guide

Choosing the right material for mechanical seal rings is not only about performance, but also about balancing cost, durability, and compatibility with your working environment. Our step-by-step guide will help you make the best choice:

Identify the Pumping Medium

Start by defining the type of liquid the seal will handle—whether it is clean water, slurry, oil, chemicals, or corrosive substances. The chemical nature of the medium is the first factor in narrowing down material options.

Evaluate Operating Conditions

Consider the pressure, temperature, and speed of the pump. High temperatures or extreme pressures often require advanced materials like silicon carbide or tungsten carbide for stable performance.

Assess Abrasion and Corrosion Risks

If the medium contains solid particles or abrasive elements, materials with high hardness such as tungsten carbide or silicon carbide are recommended. For corrosive environments, carbon and ceramic provide better resistance.

Consider Cost vs. Service Life

While premium materials may cost more initially, they can greatly reduce downtime and maintenance expenses. Stainless steel remains cost-effective for standard applications, while carbon and ceramic offer a balance between price and performance.

Match with OEM Requirements

If your pump brand requires specific OEM-compatible seals, ensure the material aligns with those specifications. We provide customized OEM solutions for brands such as Grundfos, Flygt, and Alfa Laval.

Seek Expert Consultation

Material selection can be complex when multiple factors overlap. Consulting with a seal manufacturer like Victor, with 27 years of experience, ensures you receive the right recommendation tailored to your exact application.

mechanical seal material FAQ

Which is better silicon carbide or tungsten carbide mechanical seal?

Both silicon carbide (SiC) and tungsten carbide (TC) are premium materials, but the better choice depends on your application.

Silicon Carbide (SiC): Best for chemical resistance, high temperatures, and light to moderate abrasive conditions. It is lightweight, extremely hard, and offers excellent thermal shock resistance, making it ideal for corrosive or chemical-rich environments.

Tungsten Carbide (TC): Preferred for heavy-duty and abrasive applications. It is tougher and denser than silicon carbide, with exceptional wear resistance and the ability to handle high pressure and impact conditions.

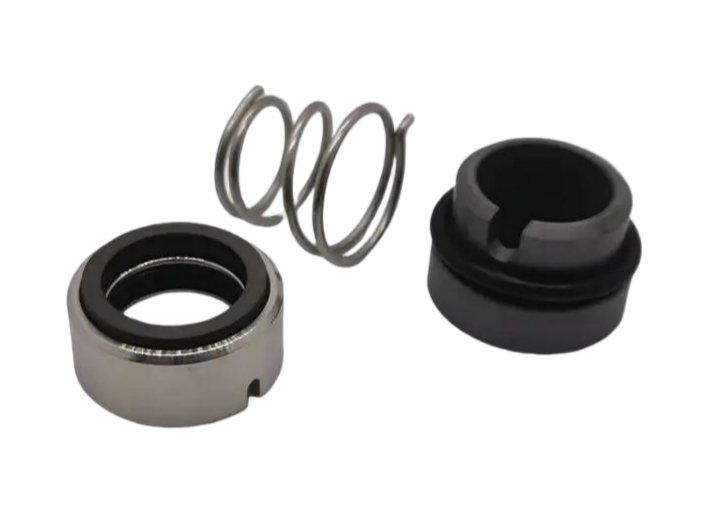

Can I use the same material for all parts of the mechanical seal?

Not usually. Mechanical seals are made of different components—rotating ring, stationary ring, secondary seals, springs, and metal parts—each facing different stresses. Using the same material for all parts may reduce performance or cause premature wear.

Seal faces: Require hardness and wear resistance (e.g., silicon carbide, tungsten carbide, or carbon).

Secondary seals (O-rings, gaskets): Need flexibility and chemical resistance (e.g., EPDM, Viton, or PTFE).

Metal parts: Must provide strength and corrosion resistance (e.g., stainless steel).

Mixing materials strategically ensures optimal sealing, durability, and compatibility with the pump’s operating environment.