Metal bellow mechanical seals use flexible corrugated metal to provide elasticity and torque transmission without springs. They offer leak-proof performance under extreme temperatures, aggressive chemicals, or vacuum environments, and can work with O-rings or flexible graphite for reliable operation across a wide temperature range.

strict compliance with global standards

Our metal bellow seals are engineered following DIN24960, EN12756, ISO3069, API610, API682, and GB6556-94 specifications, ensuring consistent quality, reliable performance, and compatibility across industrial systems.

ready stock for quick shipment

With a well-managed inventory of key models, we shorten lead times and support fast order processing—helping you replace components without delaying maintenance or daily operations.

responsive technical support

Our team provides quick after-sales assistance and troubleshooting to reduce downtime and keep your equipment operating smoothly and safely.

Metal bellow mechanical seals operate by maintaining a thin fluid film between a stationary sealing face and a rotating face. The flexible metal bellows—often welded to the stationary ring—acts both as a spring and a pressure compensating element. Under internal fluid pressure, the bellows flexes, applying a constant closing force that keeps the faces in tight contact. As the shaft turns, the rotating face follows while the stationary face remains fixed; the fluid film between them provides lubrication and cooling, minimizing wear and avoiding direct contact. Meanwhile, the bellows continuously adjusts in response to axial movement, thermal expansion, and misalignment, ensuring stable sealing performance under varying conditions.

Unlike conventional pusher-style seals, metal bellows seals eliminate dynamically loaded O-rings. Instead, a static secondary seal (like flexible graphite or a static O-ring) is used, reducing wear, friction, and potential failure points.

Because of their welded all-metal construction, these seals provide highly reliable, hermetic sealing even in extreme environments—such as high temperature, aggressive chemicals, high pressure, or vacuum systems.

Metal bellow mechanical seal materials—such as stainless steels, and high-grade carbides—provide outstanding resistance to extreme temperatures, corrosive chemicals, and thermal cycling. Their edge-welded or formed bellows eliminate dynamically loaded O-rings, allowing the seal to maintain performance in applications where elastomer seals would fail.

The bellows configuration ensures a balanced sealing design that operates independently of shaft rotation direction. This structure provides uniform face loading, reduces wear, and offers a natural self-cleaning effect. As a result, the seal maintains stable performance even in pumps handling viscous media, solids, or fluids prone to fouling.

Metal bellows materials offer flexibility to absorb shaft misalignment, vibration, and thermal expansion without compromising sealing integrity. Their compact design fits easily into limited installation spaces, while durable metal components support long service life with minimal maintenance—making them a versatile choice for demanding industrial systems.

Victor’s metal bellow mechanical seals are designed for stable performance in demanding industrial environments. Each seal is produced with strict dimensional accuracy and verified through comprehensive leak and performance testing, ensuring consistent reliability from manufacturing to final operation.

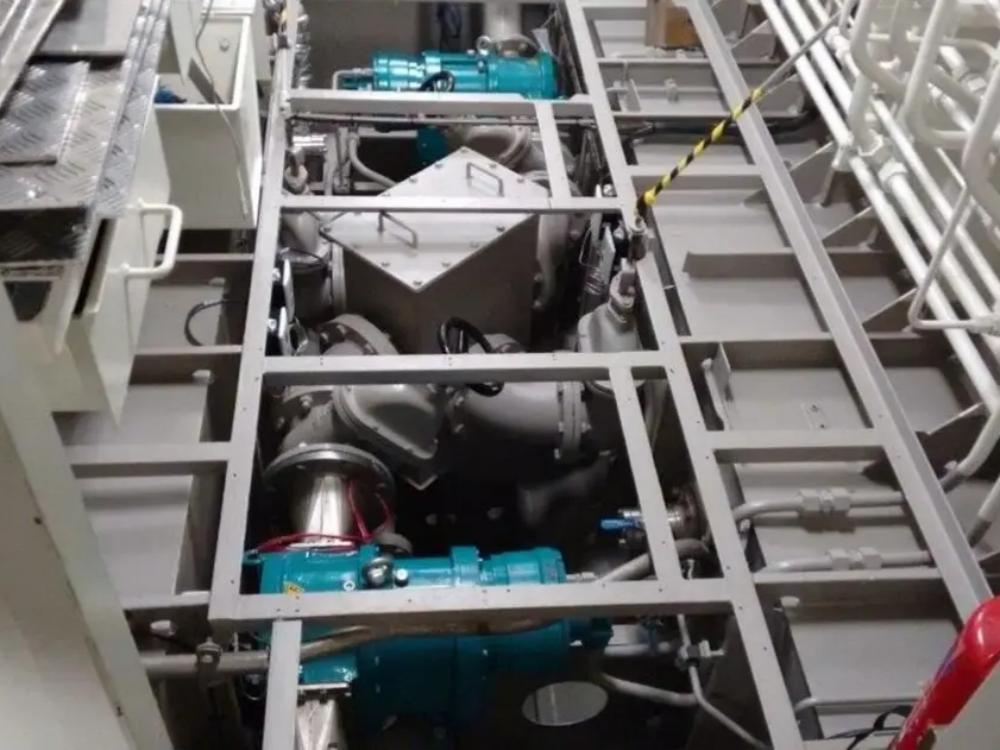

In the oil and gas sector, metal bellow mechanical seals are widely used in pumps, compressors, and subsea equipment. They excel under harsh conditions involving high pressure, high temperature, and exposure to corrosive hydrocarbons. Thanks to their all-metal construction, these seals resist degradation by aggressive fluids, minimize emissions, and deliver reliable performance even in demanding drilling, refining, and pipeline operations.

Metal bellow seals are particularly well-suited for chemical processing plants, where they maintain leak-free operation in the presence of corrosive acids, solvents, or reactive media. The corrugated metal structure provides excellent chemical compatibility and mechanical strength, while the flexibility of the bellows accommodates shaft movement and pressure fluctuations commonly found in reactors, mixers, and pumps.

In the pulp and paper industry, equipment such as slurry pumps and digestion systems often handle abrasive and high-temperature media. Metal bellow mechanical seals offer robust sealing in these environments, resisting the wear caused by wood pulp particles and harsh chemicals used in bleaching. Their long service life and ability to absorb thermal expansion make them highly reliable in continuous processing operations.

Although metal bellow seals are more common in heavy industry, they also find applications in food and beverage processing, especially in areas requiring high-temperature or high-purity sealing. The metal construction supports sterilization cycles and aggressive cleaning regimes, while eliminating elastomer springs reduces the risk of contamination — making them ideal for hygienic, high-integrity systems.

Victor applies precisely engineered material combinations for its metal bellow mechanical seals. Each seal can be configured with different materials to accommodate extreme temperatures, corrosive media, and high-pressure conditions.

Silicon Carbide (SiC / RBSiC): Silicon Carbide offers exceptional hardness, thermal conductivity, and abrasion resistance, making it ideal for high-speed and high-temperature metal bellow mechanical seals. RBSiC provides even greater strength and stability, especially in corrosive or heavily-loaded pump environments.

Tungsten Carbide (TC): Tungsten Carbide delivers outstanding wear resistance and toughness, making it a strong choice for abrasive media and high-pressure conditions. It ensures long service life in demanding applications where mechanical shock or slurry handling is common.

Carbon Graphite Resin Impregnated: Resin-impregnated carbon graphite provides low friction, excellent thermal stability, and reliable dry-running tolerance. It is commonly paired with hard faces in our metal bellow mechanical seals to achieve smooth, stable operation.

Carbon Graphite Antimony Impregnated: Antimony-impregnated carbon graphite offers higher strength and improved heat dissipation compared with standard carbon materials. It is ideal for high-load and high-pressure sealing conditions, ensuring consistent performance over long cycles.

Flexible Graphite: Flexible graphite withstands extreme temperatures and aggressive chemicals, making it suitable for metal bellow seals used in refinery, petrochemical, and high-temperature process pumps. It ensures reliable sealing even under thermal cycling.

Viton (FKM): Viton provides excellent chemical resistance to oils, fuels, and most industrial fluids. It is widely used in mechanical seals for general-purpose process pumps, maintaining elasticity and sealing performance under elevated temperatures.

EPDM: EPDM delivers strong resistance to hot water, steam, and certain chemical solutions. It is suitable for mechanical seals handling polar media where oil resistance is not required.

304 Stainless Steel: 304 stainless steel offers good corrosion resistance and structural stability for standard industrial environments. It is commonly used for springs and hardware in metal bellow seals operating in non-aggressive media.

316 Stainless Steel: 316 stainless steel provides enhanced corrosion resistance due to its molybdenum content, making it suitable for chemical processing, offshore, and chlorinated environments. It ensures durable, long-term performance for bellow seals exposed to aggressive fluids.

Acquire all kinds of knowledge from professional China pump mechanical seal manufacturer

Double-layer sealing is a road surface treatment method. It uses two layers of asphalt and aggregate. This method helps protect roads from water and traffic damage. Engineers choose this sealing method for busy roads because it is more durable than other methods. Understanding different types of mechanical seals is crucial for many industries.

Many water pump failures are caused by problems with the seals. Studies show that approximately 70% of water pump failures are caused by mechanical seal issues. Leaks are often noticed due to dry running, overheating damage, or misalignment of the seal ring. Technicians must follow safety rules and use the correct

When the water pump seal fails, coolant will leak. The engine may overheat rapidly. Early detection can prevent costly repairs. Car owners should act quickly and choose high-quality mechanical seals, such as Victor mechanical seals, to ensure vehicle safety. Key Takeaways What Happens When a Water Pump Seal Fails Coolant Leakage and Loss

The biggest difference between Type 1 and Type 2 mechanical seals lies in their manufacturing process and sealing principle. Victor’s seals are robust and durable, effectively preventing leaks in pumps and machines. Their products are of exceptional quality, which is why many companies trust Victor when they need durable and reliable products. Key Takeaways

Selecting the right metal bellow mechanical seal starts with matching the seal design to your operating conditions.

First, confirm the temperature, pressure, and chemical characteristics of the medium—metal bellows are ideal for extreme heat or aggressive fluids, but the seal face and secondary seal materials still need to be compatible.

Next, check whether the application requires a balanced or unbalanced design, single or dual seal arrangement, and whether the equipment has axial movement that the bellows must compensate for. It’s also important to consider shaft size, speed for critical services.

Finally, choose a seal supplier, such as Victor that offers reliable material traceability, customization options, and technical support, ensuring the seal can be optimized for your specific pump or process requirements.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

About Victor

Contact Victor