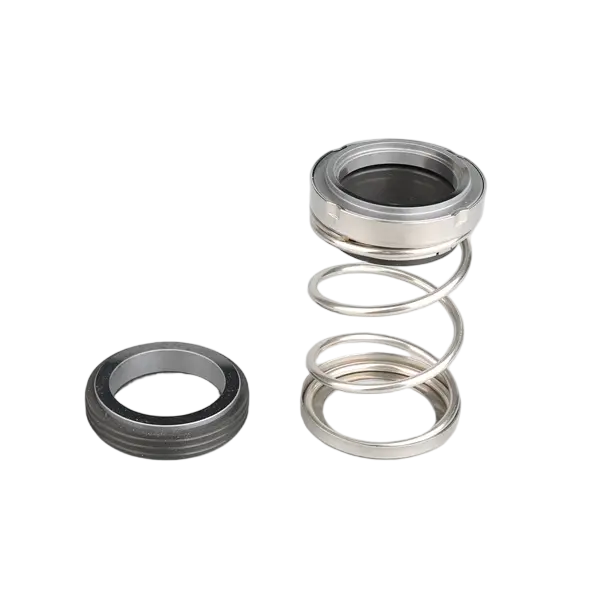

A single spring mechanical seal is a type of mechanical seal that uses a single, large coil spring to provide the necessary force to keep the seal faces pressed together. This simple design is a common and cost-effective solution for preventing fluid leakage in various types of rotating equipment, such as pumps and compressors.

Advanced CNC Machining & Premium Materials

Victor use high-precision CNC machines to manufacture metal components with tight tolerances. Only top-grade raw materials are selected for durability and performance.

Custom Mechanical Seal Development

We design tailor-made seals for unique pump requirements, ensuring optimal fit and performance in marine environments.

Fast After-Sales Response

Our team provides quick technical support and troubleshooting to minimize downtime and keep your vessels operational.

Single coil spring seal rely on one coil spring to apply a consistent axial force that keeps the rotating face pressed against the stationary face. As the shaft rotates, a thin film of the process fluid exists between the two faces, which provides lubrication and cools the sealing surfaces, preventing direct metal-to-metal contact.

The single spring also compensates for shaft movement — such as axial shift, thermal expansion, or vibration — by flexing to maintain constant contact, ensuring leak-free performance under changing operating conditions. Depending on design, the spring’s wind direction (right- or left-hand) corresponds to the shaft’s rotation to avoid spring unwinding.

Overall, this simple but robust mechanism offers reliable sealing with fewer components, reducing the risk of clogging and making maintenance easier.

Single spring mechanical seals use a straightforward pusher-type or elastomer-supported structure with an unbalanced design,. This simplicity makes them cost-effective, easy to install, and suitable for a wide range of pump types. The single conical or cylindrical spring provides uniform face loading, ensuring steady and reliable sealing performance even in applications with low solids content or fluctuating operating conditions.

These seals feature dependable torque transmission through a conical spring, bayonet drive, or O-ring compression, ensuring stable operation. Depending on the model, they can be either direction-dependent or direction-independent, providing flexibility for various shaft rotation conditions. Designs that avoid torsion on the bellows or spring further improve reliability and reduce wear.

Single spring seals support a wide range of rotary face, seat, elastomer, and metal combinations, allowing them to handle water, oils, chemicals, and light abrasive media. Their compact geometry—often with minimal outer diameter and short installation length—makes them easy to fit into tight equipment spaces. With both metric and inch sizes available, they integrate seamlessly into global pump standards and applications.

In water and wastewater applications, single spring seals are widely used in pumps that handle clean water, light chemicals, and treated effluent. These environments typically have moderate pressure and temperature, making them ideal for the straightforward design of single spring seals. The open coil of the spring allows for some self-cleaning, which is beneficial for sealing fluids that might have a small amount of solids.

* Victor recommends using an unbalanced single spring seal with an elastomer bellows, such as the Type 21, in this application for its adaptability to shaft misalignment and general reliability.

For HVAC (Heating, Ventilation, and Air Conditioning) and cooling water systems, single spring seals are a common and effective solution. These systems circulate water and other coolants at moderate temperatures and pressures, conditions that are well within the operating range of a standard single spring seal. Their ease of installation and maintenance is a significant advantage in these applications, as it helps to reduce downtime for routine service.

* Victor suggests a simple, single coil spring seal in these systems, often with a carbon face and ceramic seat, for its robust performance in clean water environments.

General industrial applications, including various centrifugal, rotary, and turbine pumps, frequently utilize single spring seals. These seals are used for a wide range of fluids, from oils and lubricants to non-hazardous chemicals. Their versatility and durability make them a go-to choice for manufacturing, processing, and other general-purpose duties where extreme conditions are not a factor.

* Victor recommends considering a balanced single spring seal for higher pressures, which provides better performance and longer life by distributing face load more evenly.

Material selection plays a decisive role in the durability and stability of single spring seals. By combining hard, soft, and elastomeric materials strategically, Victor’s single spring seals deliver balanced performance, extended service life, and reliable sealing even under fluctuating conditions.

Carbon: Carbon is widely used in single spring mechanical seals because it offers excellent lubricity, low friction, and good chemical resistance. It runs well against hard faces like SiC and TC, providing stable sealing performance.

Silicon Carbide (SiC / RBSiC / SSIC): Silicon carbide provides superior hardness, excellent thermal conductivity, and strong wear resistance, making it ideal for demanding applications. SSIC offers the highest purity and corrosion resistance among SiC options.

Ceramic: Ceramic is a cost-effective sealing face material with good hardness, chemical stability, and smooth surface finish. It is suitable for general water, light chemicals, and low-to-medium duty applications.

Tungsten Carbide (TC): Tungsten carbide offers exceptional wear resistance and strength, making it ideal for abrasive media or high-pressure conditions. It is also highly durable when paired with carbon.

NBR: NBR O-rings provide good resistance to oils and general fluids, making them a common choice for standard pump applications.

EPDM: EPDM performs well in hot water, steam, and many chemicals but is not suitable for oils. It is commonly used in water treatment and HVAC systems.

Viton (FKM): Viton offers excellent high-temperature and chemical resistance, making it ideal for aggressive media and industrial chemicals.

Aflas: Aflas provides outstanding resistance to strong chemicals, amines, and high-temperature environments, often used in oil & gas and chemical processing.

304 Stainless Steel: 304 stainless steel is cost-effective and provides good corrosion resistance for general industrial applications. It is commonly used in standard mechanical seal hardware.

316 Stainless Steel: 316 stainless steel offers enhanced corrosion resistance due to its molybdenum content, making it suitable for seawater, chemicals, and more aggressive fluids.

Acquire all kinds of knowledge from professional China pump mechanical seal manufacturer

Double-layer sealing is a road surface treatment method. It uses two layers of asphalt and aggregate. This method helps protect roads from water and traffic damage. Engineers choose this sealing method for busy roads because it is more durable than other methods. Understanding different types of mechanical seals is crucial for many industries.

Many water pump failures are caused by problems with the seals. Studies show that approximately 70% of water pump failures are caused by mechanical seal issues. Leaks are often noticed due to dry running, overheating damage, or misalignment of the seal ring. Technicians must follow safety rules and use the correct

When the water pump seal fails, coolant will leak. The engine may overheat rapidly. Early detection can prevent costly repairs. Car owners should act quickly and choose high-quality mechanical seals, such as Victor mechanical seals, to ensure vehicle safety. Key Takeaways What Happens When a Water Pump Seal Fails Coolant Leakage and Loss

The biggest difference between Type 1 and Type 2 mechanical seals lies in their manufacturing process and sealing principle. Victor’s seals are robust and durable, effectively preventing leaks in pumps and machines. Their products are of exceptional quality, which is why many companies trust Victor when they need durable and reliable products. Key Takeaways

A pump mechanical seal typically lasts between one and three years, but this can change a lot depending on several factors. Some seals can last for five years or more, while others might fail in just a few days.

The main things that affect a seal’s lifespan are:

The fluid being pumped: Abrasive or corrosive fluids will wear out a seal much faster than clean water.

Operating conditions: High temperatures, high pressure, or the pump running dry will quickly damage a seal.

Correct installation: If a seal is not installed perfectly, it can fail almost immediately.

The right seal for the job: Using a seal that isn’t designed for the specific fluid or conditions will lead to a short life.

The pressure rating for a single coil mechanical seal can vary quite a bit, but it’s generally suited for low to moderate pressure applications, typically up to around 20 bar (about 290 psi).

1. Prepare and Clean

First, make sure the pump is shut down and all power is off. Drain any fluid from the pump. Then, take apart the pump to get to the old seal. Clean the shaft, seal chamber, and all pump parts thoroughly. It’s very important to remove all old seal residue, rust, or dirt.

2. Inspect the Seal and Shaft

Carefully inspect the new seal for any damage. Make sure you don’t touch the seal faces with your bare hands, as oils from your skin can cause problems. Check the pump shaft for any scratches or nicks that could damage the new seal’s O-rings.

3. Install the Stationary and Rotating Parts

Slide the rotating part of the seal onto the pump shaft. You might need to use a clean lubricant to help it slide on smoothly. Then, install the stationary part of the seal into the pump’s seal chamber. Make sure both parts are seated correctly and are perfectly aligned.

4. Set the Seal and Reassemble

Following the manufacturer’s instructions, set the proper compression for the seal spring. This step is critical for the seal to work properly. Finally, reassemble the pump, making sure all bolts are tightened evenly to avoid any misalignment. After assembly, check for any movement of the shaft or seal to ensure everything is secure.

Single coil mechanical seal uses one large, robust coil that resists corrosion and is less prone to clogging in viscous or dirty media. However, compared with multi-spring designs, they provide less uniform face loading and require more axial space. They also depend more on rotation direction, which can limit application flexibility.

Multi-spring mechanical seals use several small springs to deliver even, consistent face pressure, giving them better performance at higher speeds and pressures. They also offer easier standardization across seal sizes. But compared with single spring seals, their thin spring wires are more susceptible to corrosion and clogging in contaminated fluids.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

About Victor

Contact Victor