A Wave Spring Mechanical Seal is a type of seal used in pumps and rotating equipment to prevent fluid leakage. Unlike traditional coil springs, it uses a wave-shaped spring that provides consistent pressure in a compact design. This makes the seal smaller, more efficient, and reliable for marine and industrial applications.

wide range of mechanical seals

At Veekter, we manufacture a full line of mechanical seals, including cartridge seals, elastomer bellow seals, and spring seals. We also produce spare parts such as seal rings, bushings, and thrust discs made from premium materials.

trusted alternatives to top brands

For more than 27 years, Veekter has supplied cost-effective replacements for global brands like EagleBurgmann, John Crane, Vulcan, AES, and Flowserve. Our products are engineered to deliver the same high performance at more competitive prices.

global reliability and fast delivery

Every seal is precision-made and rigorously tested to meet international standards. Shipbuilders and pump manufacturers worldwide trust Veekter for reliable performance, quick delivery, and long-lasting value.

Wave spring mechanical seals operate by using a wave-shaped spring to maintain consistent contact between the sealing faces. The wave spring is a specialized compression spring with a wavy profile, designed to provide a nearly uniform force across a wide range of deflection.

In a typical configuration, the wave spring is placed behind the primary ring. It applies a controlled axial force that presses the primary ring firmly against the mating ring, ensuring the seal faces remain engaged.

This axial force allows the seal to maintain tight contact even under varying conditions such as temperature changes, pressure fluctuations, and mechanical vibrations. By keeping the sealing faces closely pressed together, the wave spring prevents leakage and ensures reliable performance between the rotating and stationary components of the mechanical seal.

The wave-shaped spring delivers consistent force while taking up less axial space compared to traditional coil springs. This compact structure is especially valuable in marine and industrial pumps where equipment space is limited. It allows for easier installation, better pump integration, and improved efficiency without compromising sealing performance.

By applying uniform pressure on the sealing faces, the wave spring reduces friction, heat generation, and uneven wear. This controlled load distribution helps extend the life of the seal and pump components. In practice, it means fewer replacements, lower maintenance costs, and greater reliability for continuous operations in demanding environments.

Wave spring seals are engineered to compensate for slight shaft misalignments that often occur during operation. This tolerance reduces the risk of leaks and mechanical stress on the sealing faces. By maintaining proper contact between the faces, the wave spring reduces the likelihood of excessive wear or damage caused by uneven contact or vibration.

Veekter provides high-quality solutions for a wide range of applications. Every seal undergoes 100% dimensional inspection and pressure leakage testing, with sample checks during production, ensuring consistent reliability and performance.

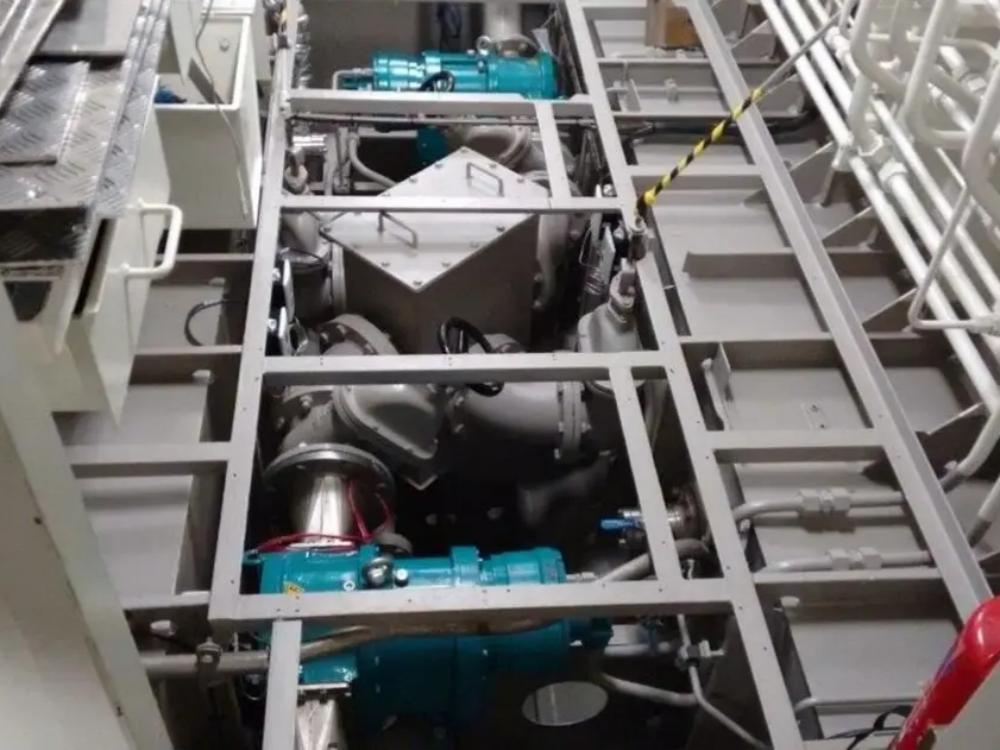

Wave spring seals are installed on the pump shaft to prevent water leakage in ballast, cooling, and bilge systems. The spring maintains even pressure on the sealing faces, ensuring reliable operation under vibration, misalignment, and harsh seawater conditions.

For centrifugal pumps, these seals secure the interface between the rotating shaft and stationary parts. They reduce friction and wear while maintaining tight contact, ensuring efficient fluid transfer and extending the pump’s service life during high-speed operation.

Wave spring seals are applied in mixers, reactors, and chemical transfer pumps to prevent leaks of corrosive or aggressive fluids. They maintain stable sealing under pressure and temperature changes, protecting both the equipment and personnel from hazardous fluid exposure.

In food and beverage pumps, wave spring seals prevent leakage in dosing, transfer, and cleaning systems. The seals provide consistent face contact, ensuring hygienic operation while resisting contamination, wear, and frequent temperature or pressure variations.

At Veekter, we do more than manufacture high-quality mechanical seals—we also provide expert guidance to help customers achieve reliable performance. Our team supports you through every step of installation, ensuring correct procedures, reduced downtime, and long-lasting seal service.

Before installation, make sure the pump is fully shut down, isolated, and depressurized. Clean the shaft, sleeve, and stuffing box carefully, and check the shaft surface for burrs or scratches that could damage the seal.

Unpack the seal gently and examine all components for visible defects. The sealing faces must be smooth and free from scratches. Apply a thin layer of clean lubricant to O-rings and sealing faces to ease assembly.

Insert the stationary seat, or mating ring, into the gland or stuffing box. Ensure it is clean, squarely aligned, and fully seated. Handle with gloves to avoid contaminating the sealing surface during installation.

Carefully slide the rotating unit, including the primary ring and wave spring, onto the shaft. Position it at the correct axial location shown in the drawing, making sure the spring sits properly behind the sealing face.

Fix the rotating assembly in place by tightening the set screws evenly. Install the gland plate with bolts, tightening them in a crisscross pattern. Recheck alignment so that the sealing faces remain parallel and square.

Turn the shaft by hand to confirm smooth movement without binding. Recheck all bolts and fasteners for tightness. During startup, run at low speed first, inspect for leaks, and then increase to full operating conditions.

Acquire all kinds of knowledge from professional China pump mechanical seal manufacturer

Double-layer sealing is a road surface treatment method. It uses two layers of asphalt and aggregate. This method helps protect roads from water and traffic damage. Engineers choose this sealing method for busy roads because it is more durable than other methods. Understanding different types of mechanical seals is crucial for many industries.

Many water pump failures are caused by problems with the seals. Studies show that approximately 70% of water pump failures are caused by mechanical seal issues. Leaks are often noticed due to dry running, overheating damage, or misalignment of the seal ring. Technicians must follow safety rules and use the correct

When the water pump seal fails, coolant will leak. The engine may overheat rapidly. Early detection can prevent costly repairs. Car owners should act quickly and choose high-quality mechanical seals, such as Victor mechanical seals, to ensure vehicle safety. Key Takeaways What Happens When a Water Pump Seal Fails Coolant Leakage and Loss

The biggest difference between Type 1 and Type 2 mechanical seals lies in their manufacturing process and sealing principle. Victor’s seals are robust and durable, effectively preventing leaks in pumps and machines. Their products are of exceptional quality, which is why many companies trust Victor when they need durable and reliable products. Key Takeaways

1.Cartridge mechanical seals

Pre-assembled units that combine the seal, gland, and sleeve.

Easy to install and replace, reducing installation errors.

Commonly used in pumps where reliability and maintenance efficiency are important.

2. Elastomer Bellow Mechanical Seals

Use a flexible elastomer bellow instead of a traditional spring to maintain face contact.

Excellent for handling corrosive or abrasive fluids and accommodating misalignment.

Often applied in chemical and marine pumps.

3. Spring Mechanical Seals

Use one or more springs (coil, wave, or garter) to maintain axial pressure on the seal faces.

Suitable for a wide range of pressures and temperatures.

Can handle variable operating conditions and are commonly used in industrial and marine pumps.

The difference between coil springs and wave springs mainly lies in their shape, size, force distribution, and application efficiency:

Shape and Structure

Coil Spring: A traditional helical spring, with continuous coils that compress or extend along its axis.

Wave Spring: A flat wire formed into a wavy pattern, creating multiple contact points in a compact, single-turn design.

Space Efficiency

Coil Spring: Requires more axial space to achieve the same deflection and force.

Wave Spring: Can provide the same force in much less space, making it ideal for compact mechanical seals.

Force Distribution

Coil Spring: Force is concentrated along the coils and may vary slightly as it compresses.

Wave Spring: Delivers more uniform and consistent axial force across the sealing face, improving contact stability.

Applications

Coil Spring: Common in general-purpose mechanical seals, simple pumps, and applications where space is not limited.

Wave Spring: Preferred in marine, chemical, and industrial pumps where compact design, consistent pressure, and longer seal life are critical.

In short, wave springs are smaller, more efficient, and provide more even force, making them ideal for high-performance mechanical seals.

A wave washer (also called a wave spring washer) should be used when you need consistent axial load in a compact space while allowing for some deflection. Its applications are ideal in situations where traditional coil springs are too bulky or do not provide uniform force.

Key Situations to Use a Wave Washer:

Space-Limited Assemblies

When axial space is restricted, such as in mechanical seals, bearings, or small pump shafts, a wave washer can provide the required spring force in a much smaller profile.

Maintaining Consistent Pressure

When consistent contact force is needed, like pressing a seal face or bearing against a mating surface, a wave washer ensures even load distribution.

Compensating for Misalignment or Thermal Expansion

Wave washers can absorb minor axial movement caused by shaft misalignment, thermal expansion, or component wear, maintaining reliable sealing or clamping.

Reducing Vibration or Noise

The washer can act as a damping element, reducing vibration in rotating assemblies like pumps, compressors, or small motors.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

About Victor

Contact Victor