Veekter is a leading OEM mechanical seal manufacturer in China, specializing in marine pump solutions. With decades of expertise, our OEM mechanical seals can be used as replacements for many world-renowned pump brands, including IMO, Grundfos, Alfa Laval, Flygt, ABS, and more. Built to match the performance of top international brands, our seals combine precision engineering, premium materials, and cost-effectiveness to support shipbuilders and pump manufacturers worldwide.

To help you better understand our capabilities and the value we bring, this article provides a complete introduction to OEM replacement mechanical seals—covering their types, and practical guidance for use and maintenance. If you’d like to explore how Veekter can support your projects with customized solutions and expert advice, we invite you to continue reading or contact our sales team directly for more details.

contact us

We manufacture mechanical seals replacement of world-famous pump brands, backed by our own advanced mechanical seal factory. With strong in-house production capacity, we carry stock of most OEM seals, enabling fast turnaround and delivery. If you are interested in OEM pump seals for your specific applications, please feel free to contact us for details.

china OEM mechanical seal manufacturer

With over 27 years of expertise and advanced CNC machining, Veekter designs and produces OEM mechanical seals in strict accordance with DIN24960, EN12756, ISO3069, API610, API682 and GB6556-94 standards.

Backed by a 3,800㎡ facility and ample inventory, our in-house production ensures continuous availability of OEM mechanical seals, reducing lead times and supporting smooth operations for customers worldwide.

Our engineering team develops customized mechanical seals for specific pump applications, providing precise design support, sample validation, and responsive after-sales service to ensure long-term reliability worldwide.

Veekter OEM replacement mechanical seals are engineered to exact dimensions, ensuring full compatibility with original pump designs. This precise matching minimizes the risk of leaks and operational inefficiencies.

Our seals are manufactured using premium materials and advanced machining processes, improving operational stability and reducing wear under demanding marine and industrial conditions.

With rigorous quality control and the use of high-grade materials such as Silicon Carbide, Tungsten Carbide, Ceramic, Veekter seals offer resistance to corrosion, abrasion, and extreme temperatures.

Designed as direct replacements, Veekter OEM seals can be installed without modifying the pump, saving time and reducing the risk of installation errors while maintaining reliable operation.

If you have a question about our products or need help with a custom mechanical seal solution, we’d love to hear from you. Give us a few details regarding your project and we’ll be happy to help.

Provide your pump type, operating conditions, and technical requirements. Veekter’s engineers review the details to recommend suitable mechanical seal solutions that meet your application needs.

Our team analyzes the provided specifications, including dimensions, materials, and working environment. This step ensures the seal design will perform reliably under the intended conditions.

Veekter manufactures prototype seals based on the evaluation results. Samples are tested for fit, performance, and durability before full-scale production to guarantee quality and reliability.

After testing and client confirmation, the seal design is finalized. We proceed with precision manufacturing under strict quality control, ensuring every component meets international standards.

Finished OEM mechanical seals are shipped to the client. Veekter provides ongoing support for installation, troubleshooting, and maintenance guidance to ensure optimal performance.

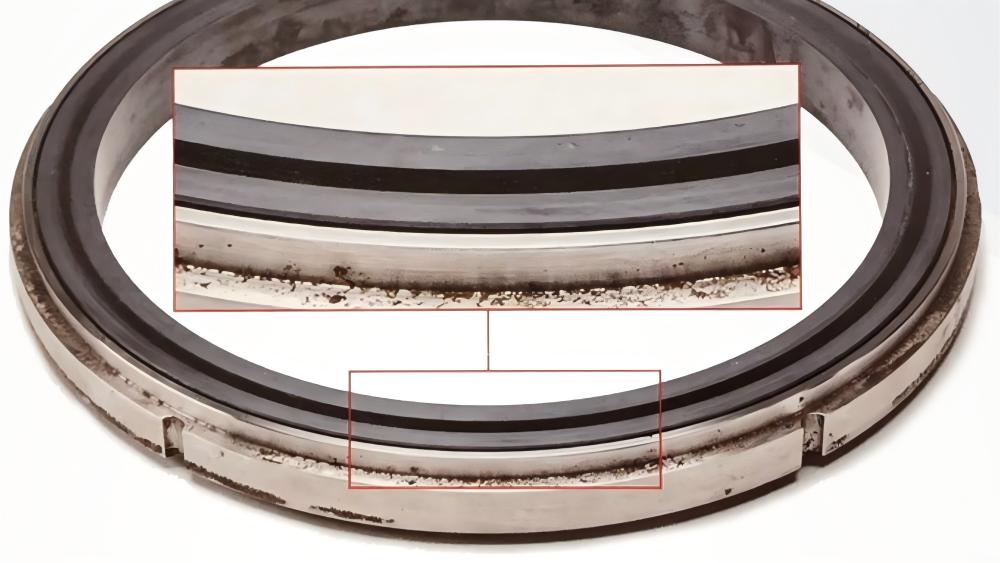

We provide a complete range of direct-replacement mechanical seals suitable for widely used marine pumps around the world. All our seals are manufactured to strict quality standards using premium materials, allowing them to serve as exact replacements without any modification, fully compatible with the original OEM pumps. Below are the most common maintenance issues and their solutions. If your problem is not listed or requires further assistance, please contact us for personalized support.

Acquire all kinds of knowledge from professional China pump seal manufacturer

Double-layer sealing is a road surface treatment method. It uses two layers of asphalt and aggregate. This method helps protect roads

Many water pump failures are caused by problems with the seals. Studies show that approximately 70% of water pump failures are

When the water pump seal fails, coolant will leak. The engine may overheat rapidly. Early detection can prevent costly repairs. Car owners

The biggest difference between Type 1 and Type 2 mechanical seals lies in their manufacturing process and sealing principle. Victor’s seals are robust and

A flush works by introducing clean process fluid or compatible liquid into the seal chamber. Its main purpose is to remove heat, flush away particles, and maintain a stable fluid film between the seal faces. The advantages of a flush include improved seal cooling, reduced wear, and prevention of dry running. Flush systems are most suitable for pumps handling clean or mildly contaminated fluids, high-temperature liquids, or applications with fluctuating operating conditions.

A quench functions by supplying an external liquid—often water or a compatible fluid—outside the seal faces, typically to dilute or cool any leakage from secondary seals. Its main advantages are protection against corrosive or high-temperature fluids and prevention of crystallization or hardening of residues around the seal. Quench arrangements are ideal for pumps handling hazardous, viscous, or crystallizing fluids where additional cooling and isolation are required to protect the seal and surrounding components.

Veekter’s engineers can recommend the proper flush or quench setup depending on your pump type, operating conditions, and fluid characteristics, ensuring optimal seal performance and extended service life.

The service life of an OEM mechanical seal typically ranges from 1 to 3 years under standard operating conditions. However, this lifespan can vary significantly based on several factors, including operating environment, fluid characteristics, seal design, and maintenance practices.

Factors Influencing Seal Life

Operating Conditions: Seals subjected to high temperatures, pressures, or speeds often experience reduced lifespans. For instance, pumps operating in cyclic conditions or with abrasive fluids may encounter premature wear.

Seal Design and Material: Seals made from high-quality materials like Silicon Carbide or Tungsten Carbide, and those designed to handle specific applications, tend to last longer.

Maintenance Practices: Regular maintenance, including proper installation, alignment, and monitoring, can significantly extend the life of mechanical seals.

Industry Standards and Expectations

According to the Fluid Sealing Association, operating a seal at its specified limits—such as pressure, speed, or temperature—can result in a minimum lifespan of 2 to 3 years, with some seal types, like those specified in Standard API 682, achieving this duration under steady-state conditions.

Mechanical seals and oil seals serve different purposes, so “better” depends on the application.

Mechanical Seal

Working Principle: Uses two flat, precision-machined faces (one stationary, one rotating) to prevent fluid leakage.

Advantages: Can handle high pressures, high speeds, and aggressive or hot fluids; provides a reliable, long-term sealing solution for pumps, mixers, and rotating equipment.

Best Application: Industrial pumps, marine pumps, chemical processing equipment, and applications requiring durability and minimal leakage.

Oil Seal

Working Principle: Uses an elastomer lip in contact with a shaft to prevent lubricant leakage and block external contaminants.

Advantages: Simple, low-cost, easy to install and replace; effective in retaining grease or oil in low-pressure environments.

Best Application: Gearboxes, automotive engines, axles, and rotating shafts where conditions are less demanding.

Conclusion:

If the system involves high pressure, high temperature, or corrosive fluids, a mechanical seal is the better choice.

If the application is low pressure, requires basic lubrication retention, and cost-effectiveness, an oil seal is more suitable.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

About Victor

Contact Victor