Dual seals have two sealing surfaces. These surfaces help prevent leaks in pumps and compressors. Many industries use this technology to ensure safe and efficient operation. Veekter has over 27 years of experience in mechanical seals. His work spans a wide range of industries, including marine, oil and gas mechanical seals, etc. Mechanical seal failure can cause serious problems.

- 13% of all mechanical seal failures are caused by bearing problems.

Industries such as petrochemical plants, chemical processing, pharmaceuticals, pulp and paper, and power generation require dual seals in critical processes.

Key Takeaways

- Dual seals have two sealing surfaces that prevent leaks. They work together in pumps and compressors to make equipment safer and more reliable.

- Chemical plants and oil companies use dual seals because they are used to handle hazardous fluids. Dual seals help meet safety regulations.

- Dual seals require regular maintenance. You should frequently check for leaks and monitor the fluid level to ensure proper functioning. This helps extend service life and improve performance.

- A barrier fluid is located between the seals; it reduces friction, controls temperature, and prevents contamination, thus ensuring proper seal function.

- Choosing the optimal dual seal configuration is crucial. You can choose between tandem or face-to-face configurations. The right choice helps ensure every task is completed smoothly.

Double Seal Basics

Double seal Definition

A dual seal is a type of mechanical seal. It has two main sealing surfaces with a special fluid zone in between. This configuration helps prevent leaks in pumps and compressors. The two seals work together to prevent fluid or gas leakage. Many industries use dual seals to comply with stringent safety and environmental regulations. These seals provide additional protection when handling hazardous or valuable materials. The space between the two seals is typically filled with a barrier fluid or buffer. This fluid helps control the sealing area, thus extending the seal’s service life.

Note: Dual seals are commonly used for hazardous or valuable liquids. They help prevent leaks and ensure the safety of workers and the environment.

Double seal Key Features

Dual seals have several important characteristics that distinguish them from single seals:

- Two sealing surfaces work together, providing a backup in case one fails.

- The design uses a barrier fluid or buffer for better cooling and lubrication.

- Dual seals can withstand higher pressures and temperatures than single seals.

- They can almost completely prevent leaks of liquids or gases, helping to meet zero-emission regulations.

- These seals offer greater safety and reliability, especially in critical operations.

- Dual seals require less frequent replacement, saving money and time.

- Two seals allow for better control of the sealing area, extending equipment life.

- Manufacturers use high-strength materials such as 316 stainless steel and Hastelloy C®, as well as special elastomers, to manufacture dual seals. These materials help extend the seal’s lifespan and enable it to function properly in harsh environments.

| Feature | Benefit |

|---|---|

| Two sealing faces | Backup protection and higher reliability |

| Barrier/buffer fluid | Better cooling and lubrication |

| Strong materials | Long service life |

| Leak prevention | Zero emissions and safety |

| High pressure handling | Works in tough environments |

Dual seals help businesses avoid costly maintenance and ensure stable equipment operation. Therefore, dual seals are an ideal choice for industries requiring robust and reliable seals.

How Double Mechanical Seal Works

Sealing Mechanism

Dual mechanical seals employ two sets of sealing surfaces. These sealing surfaces prevent fluid leakage. The primary sealing surface is very flat. One sealing surface is stationary, while the other rotates with the shaft. Fluid pressure and spring force bring the two sealing surfaces tightly together, forming a tight seal that prevents leakage. A very small gap, approximately 1 micrometer wide, exists between the sealing faces. A thin layer of liquid exists within this gap. This liquid helps reduce friction and wear, extending the seal’s lifespan. Due to the extremely small gap, there is virtually no liquid leakage, making leaks almost undetectable.

Note: This thin layer of liquid helps keep the seal cool and allows for smooth flow, preventing dust and other foreign matter from entering the seal.

Dual mechanical seals perform best in controlled environments. Appropriate temperature, pressure, and fluid conditions contribute to proper seal operation. Harsh environments can lead to premature seal failure. Veekter seals undergo rigorous testing, including the CTB test, designed to verify their ability to withstand high temperatures and pressures. Veekter’s unwavering commitment to quality ensures its seals operate reliably under demanding conditions.

Routine maintenance helps extend the service life of dual mechanical seals. The team should check for leaks and clean the seal faces. They should monitor temperature and pressure. The airlock fluid level must be maintained within the appropriate range. Employees should be trained on the correct operation of the seals.

- Key maintenance steps include:

- Checking for leaks or damage

- Cleaning the seal faces and O-rings

- Monitoring temperature, pressure, and vibration

- Checking and replacing the airlock fluid

- Training employees on the correct operating procedures

Inboard and Outboard Seals

Dual mechanical seals consist of two main parts: an inner seal and an outer seal. The inner seal is located near the fluid inside the pump and its function is to prevent fluid leakage into the space between the seals. The outer seal is located outside the pump and its function is to prevent any fluid or airlock fluid from leaking into the air.

This dual-seal design provides additional protection. If the inner seal fails, the outer seal serves as a backup. This design helps businesses comply with safety and environmental regulations and protects workers and equipment from hazardous leaks.

Controlling the environment surrounding the seal is crucial. Good design and maintenance help extend the seal’s lifespan. Even the best seals will wear out quickly if environmental management is poor. Veekter seals are designed to withstand harsh environments. Their meticulous design and testing make them ideal for numerous industries.

Tip: Always choose the appropriate seal design based on the application. Keep the environment around the seal stable. This helps dual mechanical seals perform at their best.

Applications of Double Seal

Double seal Industry Use Cases

Many industries use dual seal technology to ensure equipment safety. It also helps protect the environment. Veekter mechanical seals play a vital role in the following areas:

- Chemical and Petrochemical: Workers use dual seals when handling hazardous fluids. These fluids may be corrosive, toxic, or flammable. Dual seals prevent leaks and ensure personnel safety.

- Oil and Gas: Refineries and offshore platforms require dual seals. Used in pumps and compressors, they help safely transport and handle valuable resources.

- Pharmaceutical and Food Processing: Dual seals keep food and pharmaceuticals clean. They prevent contamination and ensure product safety.

- High-Pressure Systems: Dual seals operate effectively in high-pressure environments. They can also withstand drastic temperature changes, such as in power plants and marine pumps.

Veekter has extensive experience in the marine, chemical, water treatment, and oil and gas industries. Their seals operate in harsh environments, helping companies comply with safety regulations.

Dual seals effectively block bacteria, allergens, and contaminants from food and beverages. They form a tight seal, preventing bacteria and particulate matter from entering. This helps maintain cleanliness and ensure product quality.

Double seal Safety and Compliance

Dual seals provide robust safety for critical systems. They help companies prevent leaks and reduce contamination. Many industries must comply with stringent regulations, such as API, ASME, and ISO standards. Dual seals help meet the requirements of these regulations.

| Benefit | Description |

|---|---|

| Leak Prevention | Double seals make a strong barrier. They stop leaks and contamination. |

| Compliance with Standards | They help companies follow safety and industry rules. |

| Reduction in Incidents | Companies had 15% fewer leaks after using double seals. |

| Decrease in Chemical Spills | Chemical spills dropped by 20% with double seals. |

Double seals have a higher initial cost due to their complex structure and high strength. However, over time, they can save on maintenance costs and help systems operate more efficiently. Therefore, they are a wise choice for large plants that require good sealing.

Double seal Barrier Fluid vs Buffer Fluid

Barrier Fluid Role

In dual mechanical seals, the spacer fluid is crucial. Located between the two sealing surfaces, it helps improve sealing performance. Veekter Seals uses spacer fluid to ensure the safe operation of pumps. The pressure of the spacer fluid must be higher than the pressure of the process fluid to prevent leaks and keep harmful substances out.

- Lubrication: The spacer fluid reduces friction and wear on the sealing surfaces.

- Heat Transfer: The spacer fluid carries away heat from the seal, keeping it cool.

- Contamination Prevention: The spacer fluid prevents process fluid leaks and prevents dust ingress.

- Pressure Maintenance: The spacer fluid maintains a higher pressure, thus preventing leaks.

- Corrosion Prevention: The spacer fluid protects the seal from rust and damage.

- Seal Face Cooling or Heating: The spacer fluid can cool or heat the sealing surfaces depending on the application requirements.

The spacer fluid helps extend the service life of dual seals and enables them to function properly in harsh environments. Veekter products use high-efficiency spacer fluids suitable for high-pressure and corrosive chemical environments.

Buffer Fluid Role

Buffer fluids differ from spacer fluids. They are suitable for systems without additional pressure. The buffer solution is located between the two seals but does not apply additional pressure. The buffer helps protect the seals and keep them clean.

- In non-pressurized systems, the buffer solution flows in a reservoir connected to the seals.

- It is suitable for pressureless dual seals and conforms to API 682.

- The buffer solution protects the seals by preventing leaks and reducing friction.

- It keeps the sealing surfaces clean and helps extend the life of the seals.

The buffer solution itself does not prevent leaks through pressure. It helps control temperature and prevents contaminants from contacting the sealing surfaces. Veekter seals use buffer solution in low-pressure but protective applications.

Impact on Seal Performance

The isolation fluid and buffer solution help dual seals function properly. They protect the sealing surfaces and ensure equipment safety. The table below shows how each fluid affects seal performance:

| Feature | Description |

|---|---|

| Buffer Fluid Circulation | The buffer solution is circulated between the seals at a pressure lower than that of the process fluid. |

| Temperature Control | Absorbs heat generated by seal friction, preventing damage. |

| Contamination Prevention | Prevents dust and harmful substances from contacting the seal surfaces. |

| Environmental Safety | Prevents leakage of hazardous fluids, suitable for toxic or corrosive operations. |

| High-Pressure Tolerance | Withstands high pressure and high temperature, meeting the needs of heavy-duty operations. |

Barrier fluid provides strong protection in high-pressure operations. Buffer fluid is suitable for lower pressure applications where safety is still critical. Veekter’s dual seals utilize two fluids to match different operational requirements. This helps businesses ensure safe and efficient equipment operation.

Double Mechanical Seal Configurations

Dual mechanical seal configurations help engineers select the appropriate configuration for each job. Each type has its own characteristics that affect how the seals operate in pumps and compressors. There are three main types: back-to-back, face-to-face, and tandem.

Back-to-Back

In a back-to-back configuration, the two seals are positioned away from each other. This allows the outer seal to provide strong backup pressure. The shorter length allows for installation in confined spaces. The sealing faces are aligned, resulting in smooth operation. However, this design cannot withstand excessive fluid pressure. It cannot withstand reverse pressure unless a double-balanced design is used. Sometimes, the product may mix with other fluids.

Face-to-Face

In a face-to-face configuration, the sealing faces are opposite each other. This design is simple in structure and allows for more seal movement. It is suitable for solid and dirty fluids. The outer seal cannot provide sufficient backup pressure. If the fixed part is damaged, the reliability of the seal will decrease. Many engineers prefer this configuration because it is easy to maintain.

Tandem

A tandem sealing unit installs two seals side-by-side, facing the same direction. This type of seal can withstand high pressure and is ideal for sealing hazardous fluids. The first seal is used to seal the process fluid. The second seal serves as a backup in case the first seal fails. If the first seal breaks, the second seal can stop the leak. Typically, the space between the two seals is filled with an inert gas to reduce contamination. Tandem seals are commonly used in high-risk pipelines. This design is more difficult to manufacture and more expensive, but it provides an extra layer of safety.

International standards such as API 682 help in the design of dual mechanical seals. These standards specify the types of seals, materials, and piping layouts. They can help companies select the optimal seal for each project.

| Configuration | Advantages | Disadvantages |

|---|---|---|

| Back-to-Back | Strong backup pressure, compact size, aligned seal faces | Low barrier fluid pressure, no back pressure |

| Face-to-Face | Simple structure, can handle solids, wider range of motion | No full backup pressure, lower reliability in case of failure |

| Tandem | Can withstand high pressure, suitable for hazardous fluids | More difficult to manufacture, more expensive, longer size |

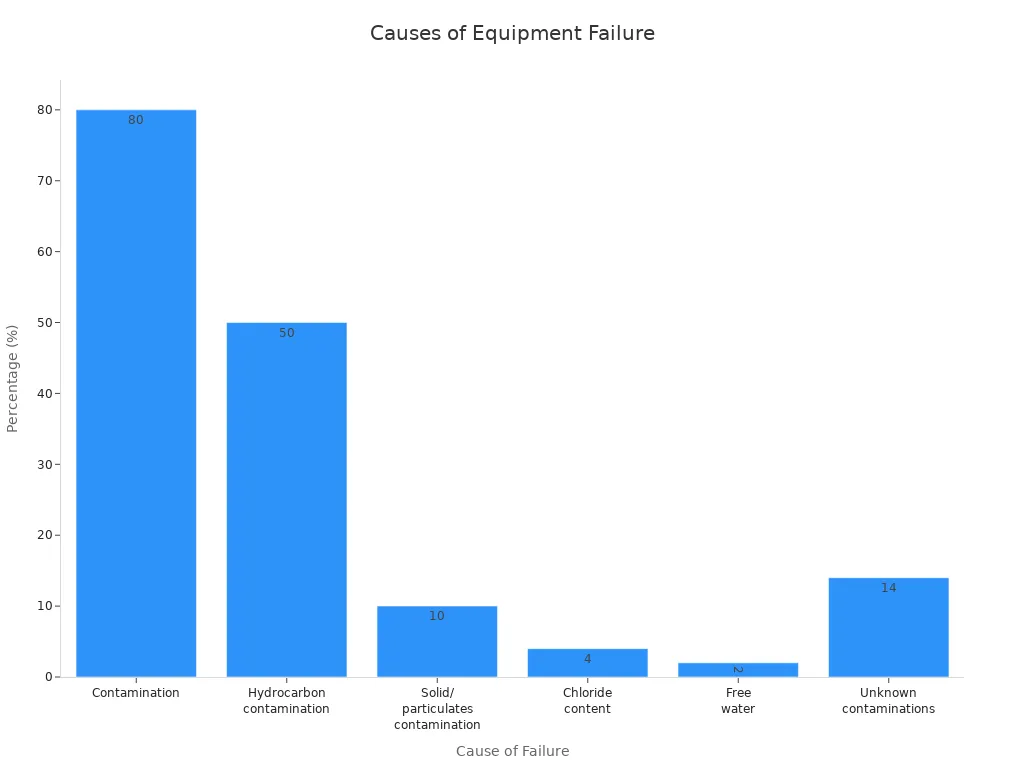

Dual seals help ensure safe and efficient machine operation. They prevent leaks and extend equipment life. Most problems are caused by contamination. The table below lists the main causes:

| Cause of Failure | Percentage |

|---|---|

| Contamination | 80% |

| Hydrocarbon contamination | 50% |

| Solid/particulates contamination | 10% |

| Chloride content | 4% |

| Free water | 2% |

| Unknown contaminations | 14% |

Veekter is committed to manufacturing superior seals.

- Double seals can reduce leaks by up to 40%.

- More and more companies are using mechanical seals in large industrial enterprises.

Double seals offer several advantages:

- They help keep the environment clean by preventing leaks.

- They help machines operate reliably even under harsh conditions.

- Many companies use double seals because they are safe and reliable.

Veekter seals perform exceptionally well even under harsh operating conditions.

FAQ

What are the main uses of double seals?

Double seals prevent leaks in pumps and compressors. They have two sealing surfaces that prevent fluid or gas leakage. This helps protect people and the environment.

How do double seals improve safety?

Double seals provide a backup in case one seal fails. If the first seal fails, the second seal can stop the leak. This extra layer of protection helps businesses comply with safety and environmental regulations.

Which industries most commonly use double seals?

Industries such as chemical, oil and gas, marine, and water treatment use double seals. These industries use hazardous or valuable fluids and require strong seals to prevent leaks.

What is the difference between a barrier fluid and a buffer fluid?

A barrier fluid is located between the seals and its pressure is higher than that of the process fluid. It prevents leaks and keeps the seals cool. A buffer fluid does not have additional pressure. It helps clean and protect the sealing surfaces.