Mechanical seals in pumps can handle many pressures. Most pump seals work up to 150 psi. Some special seals can reach 3,500 psi. Victor’s metal bellow mechanical seal works in hard conditions. Their single spring mechanical seal is for easier jobs. Knowing these pressure limits keeps people and machines safe in many ways:

- It stops leaks from getting too big and causing spills.

- It helps companies follow safety and environment rules.

- It keeps pumps safe and helps systems work well.

- It saves fluid and means fewer repairs are needed.

Key Takeaways

- Mechanical seals can handle many pressures. Most seals work up to 150 psi. Some seals can go up to 3,500 psi.

- Picking the right seal is very important. It stops leaks and keeps people safe. It also helps pumps work well.

- How you install seals is important. Good installation helps seals last longer. Support systems help seals work better.

- Checking seals often is important. Inspections find problems early. This stops expensive seal failures.

- Using the right materials helps seals work well. Strong metals and good designs help seals handle high pressure.

Maximum Pressure for Pump Seals

Industry Pressure Standards

Industry standards help people pick the right pump seals. Pressure ratings depend on the pump and seal design. Many centrifugal pump seals work up to 150 psi. Cooling water systems use unbalanced seals for 50 to 150 psi. High-pressure rotary seals can go up to 3,500 psi. Medium-pressure rotary seals work up to 500 psi. Boiler feed pumps use balanced seals for over 500 psi.

Tip: Always look at the pressure rating before you install pump seals. This stops leaks and keeps things safe.

The table below shows pressure ratings for seal types and pump systems:

| Type of Seal | Maximum Pressure Rating | PV-Rating |

|---|---|---|

| Medium-Pressure Rotary Seals | up to 500 psi | 5.0 to 9.0 |

| High-Pressure Rotary Seals | up to 3,500 psi | 7.0 to 9.0 |

| Pump Type | Pressure Range (PSIG) | Seal Type |

|---|---|---|

| Cooling Water Systems | 50-150 | Unbalanced Seal |

| High-Pressure Boiler Feed Pumps | 500+ | Balanced Seal |

Groups like API make rules for testing and safety. API Standard 682 gives rules for mechanical seals in pumps. The API 682 Integrity Test uses a reservoir with 1.7 bar (25 psig) pressure. The test lets the pressure drop by only 0.14 bar (2 psig) in five minutes. This checks if the seal holds pressure and keeps leaks small.

| Test Type | Pressure (bar) | Allowable Leakage Limits |

|---|---|---|

| API 682 Air Test | 1.7 | Pressure drop cannot exceed 0.14 bar (2 PSI) in five minutes |

| Liquid Leakage (Qualification) | N/A | Maximum 5.6 g/h per pair of sealing faces |

| Vapor Leakage (EPA Method 21) | N/A | Maximum 1000 ppm (vol) |

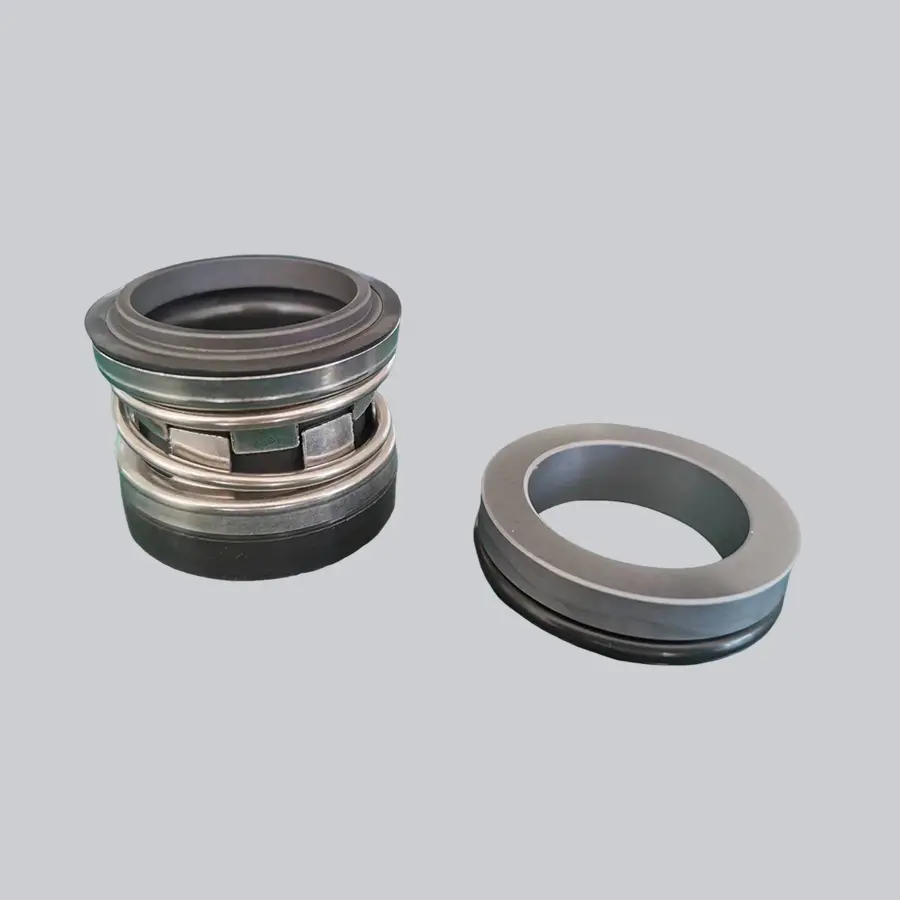

Victor Mechanical Seal Capabilities

Victor makes pump seals for many jobs and pressures. Their single spring mechanical seal works in light-duty pumps. These are used in home water systems and irrigation. These seals handle up to 150 psi. For harder jobs, Victor has metal bellow seals and cartridge seals. Metal bellow seals work with high heat and strong chemicals. They are good for chemical plants and marine pumps. These seals can handle up to 3,500 psi.

Victor tests every seal with strict rules. Each seal gets checked for size and leaks. The company follows API Standard 682 for design and testing. Victor’s seals meet the rules for pressure drop and leaks. This means they work well in tough jobs.

- Victor’s pump seals include:

- Single spring seals for light-duty pumps (up to 150 psi)

- Metal bellow seals for high-pressure and corrosive places (up to 3,500 psi)

- Cartridge seals for easy setup and fixing

Victor’s engineers check each seal for pressure and leaks. They use the API 682 Integrity Test. This test only allows a small pressure drop and leak. It helps stop problems like O-ring extrusion and spring bending. These problems can happen when pressure is high.

| Failure Mode | Description |

|---|---|

| O-ring Extrusion | High pressure puts stress on the O-ring. This can cause wear or early failure. |

| Thermal Wear | Too much friction makes heat. This can melt or hurt the O-ring or V-ring. |

| Spring Permanent Deformation | Springs can bend and not work right. This can stop the seal from working. |

Victor’s pump seals help pumps stay safe and work well. Their products follow industry rules and pass hard tests. This makes Victor a trusted choice for shipbuilders, chemical plants, and water treatment plants.

Factors Affecting Pressure Limits

Seal Design

Seal design is important for pressure limits. Engineers pick the right shape and size for each job. Balanced seal rings help spread pressure out. This makes seals last longer and work at higher pressures. Features like face width and groove depth matter too. Victor’s team checks these things during tests. They make sure seals work well in tough places.

Note: Balanced mechanical seals lower the force on seal faces. This helps them work better when pressure is high.

Materials Used

The materials in seals change how much pressure they can take. Strong metals like Inconel and Hastelloy handle very high pressure and heat. Stainless steel is good for medium pressure. PTFE coatings resist chemicals but work best at lower pressure. Picking the right material helps seals last longer and stay safe.

| Material | Pressure Rating | Temperature Resistance | Chemical Compatibility |

|---|---|---|---|

| Inconel | High | Excellent | Good |

| Stainless Steel | Moderate | Good | Excellent |

| Hastelloy | Very High | Excellent | Excellent |

| PTFE Coatings | Low to Moderate | Good | Excellent |

Metal seals must handle steady pressure and quick spikes. Seals should be rated higher than the highest pressure expected. It is best to use only 80% of the seal’s top rating. If pressure gets too high, seals wear out faster.

Operating Conditions

Things like temperature and fluid type change how seals work. Some elastomers do well in heat, but others break down fast. Viton works up to 400°F. EPDM rubber may fail above 300°F. Seal faces made from silicon carbide and tungsten carbide do better in heat than carbon-graphite. Changes in pressure also affect seals. Balanced designs help seals stay tight and stop leaks.

- Materials act differently when temperatures change.

- Hard seal faces last longer in hot or harsh fluids.

- Pressure spikes make seals work harder.

Installation Quality

How seals are installed affects how much pressure they hold. Good installation helps seals last longer and work better. Seals need the right support systems. If a seal fails, the support system may not be right. Victor’s engineers test seals and check how they are installed. They make sure seals meet their pressure ratings.

- Good installation helps seals last longer.

- Support systems help seals work in tough places.

- Careful testing and setup stop leaks and failures.

Pressure Ratings and Seal Selection

Matching Seal to Pump Requirements

To pick the right seal, you must know what the pump needs. Engineers look at how much pressure is at the pump’s suction. They also check the pressure difference the seal must handle. They look at the discharge pressure and focus on the seal chamber. The seal cannot go over its static pressure limit. If the static limit is okay, they check the dynamic limit. The dynamic limit depends on what the seal is made of and the fluid’s properties. A vapor pressure margin of at least 50 psi helps stop the fluid from turning into vapor at the seal faces. Sometimes, engineers use orifices or bushings to control flow and pressure. For some jobs, they use a different piping plan, like Plan 53B, for higher pressures.

Here are the steps for picking a pump seal:

- Look at the pump’s suction and discharge pressures.

- Check the seal chamber pressure.

- Make sure the seal’s static pressure rating is enough.

- Check the dynamic pressure limit for the seal material.

- Add a vapor pressure margin of at least 50 psi.

- Change flow and pressure if needed.

- Pick the right piping plan for the job.

Choosing the right seal stops leaks and keeps things safe. Good seals protect equipment and keep fluids inside. They also help the pump work better and last longer.

Safety Margins

Safety margins are important when picking seals. Engineers choose seals that can handle 10–20% more than the highest pressure expected. This extra strength helps the seal deal with pressure spikes and old parts. Seals with a safety margin stay safe even if parts bend or the system gets too full. This keeps the pump working and stops sudden problems.

Tip: Always pick a seal with a higher pressure rating than the system’s normal pressure.

Manufacturer Specifications

Manufacturers give important facts about seal ratings and limits. These facts include the highest pressure, temperature range, and what materials work with the seal. Following these rules makes sure the seal works right. Victor has OEM alternatives that are as good as top brands but cost less. Their cartridge seals are easy to install and save time. Over time, these features mean less maintenance and better results.

Engineers should always check the manufacturer’s data before picking a seal. This step helps stop mistakes and makes sure the seal fits the pump, especially in dangerous places.

Practical Examples and Applications

Real-World Scenarios

Mechanical seals are used in many industries. In ships, Victor’s cartridge seals keep seawater out of engines. These seals work with high pressure and lots of movement. Chemical plants use balanced mechanical seals to stop leaks. These seals protect workers and equipment from harm. They often face pressures over 1,000 PSI. Water treatment plants use metal bellow seals. These seals handle strong fluids and keep systems safe.

| Industry | Application | Seal Type | Pressure Range |

|---|---|---|---|

| Marine | Ballast pumps, engine cooling | Cartridge, Metal Bellow | Up to 3,500 PSI |

| Chemical Processing | Reactor feed pumps, mixers | Balanced, Metal Bellow | 1,000+ PSI |

| Water Treatment | Sludge pumps, chemical dosing | Metal Bellow | Up to 1,500 PSI |

Case Studies

At a chemical plant, engineers picked Victor’s balanced mechanical seals. These seals were used in a reactor feed pump. The seals faced strong acids and high heat. The special materials stopped corrosion and kept the seal tight. They worked well even above 1,000 PSI. This helped lower leaks and meet safety rules.

A water treatment plant used Victor’s metal bellow seals in sludge pumps. The seals handled pressure spikes and rough fluids. Inspections showed little wear after months of use. The plant did not need costly shutdowns. Clean water was kept safe for everyone.

Regular inspections are very important for mechanical seals. They help find wear, misalignment, or damage. This lets workers fix problems before they get worse.

Lessons Learned

Mechanical seals can fail if pressure limits are not followed. Too much pressure pushes seal faces together. This makes heat and causes damage. Over-torque can break bolts or crack housings. Under-torque can cause leaks or loose joints.

| Failure Type | Consequences |

|---|---|

| Over-Torque Dangers | Bolt failure, gland cracking, housing damage, gasket crushing |

| Under-Torque Problems | Joint separation, vibration loosening, gasket leakage |

Best practices include:

- Make a regular inspection plan to find problems early.

- Install and align seals the right way.

- Use enough lubrication to keep seals cool.

- Teach staff about maintenance and new seal technology.

Never let the seal run dry. Without liquid, heat builds up fast and can destroy the seal.

These tips help engineers pick the right seal and keep systems safe.

Mechanical seals can handle different pressures because of how they are made and what they are made from. The table below shows some common seal types and how much pressure they can take:

| Seal Type | Pressure Rating |

|---|---|

| Rubber Bellow Seals | Low pressure (up to 7 bar) |

| O-ring Pusher Seals | Medium pressure (10–25 bar) |

| Cartridge Seals | Higher pressures (25+ bar) |

| Metal Bellow & Dry Gas Seals | Very high pressure (40+ bar) |

You need to pick the right seal for the job. Think about what the seal is made of, how hot it gets, and how much pressure there is. Picking the right seal keeps pumps working well and safe.

Picking the right seal is very important. It helps pumps last longer and stay safe, especially when pressure is high.

Looking at the manufacturer’s information helps engineers stop problems and save money. Victor’s mechanical seals work well in many different jobs.