WMFL85N Metal Bellow Mechanical Seals Replace Eagle Burgmann MFL85N

Features

For unstepped shafts

Single seal

Balanced

Independent of direction of rotation

Metal bellows rotating

Analogue for

Burgmann MFL85N, Chesterton 886, John Crane 680, Latty B17, LIDERING LMB85

Advantages

For extreme temperature ranges

No dynamically loaded O-Ring

Self-cleaning effect

Short installation length possible

Pumping screw for highly viscous media available (dependent on direction of rotation)

Recommended applications

Process industry

Oil and gas industry

Refining technology

Petrochemical industry

Chemical industry

Hot media

Cold media

Highly viscous media

Pumps

Special rotating equipment

Oil

Light hydrocarbon

Aromatic Hydrocarbon

Organic solvents

Week acids

Ammonia

Operating range

Shaft diameter:

d1 = 16 … 100 mm (0.63″ … 4“)

Externally pressurized:

p1 = … 25 bar (363 PSI)

Internally pressurized:

p1 <120 °C (248 °F) 10 bar (145 PSI)

p1 <220 °C (428 °F) 5 bar (72 PSI)

Temperature: t = -40 °C … +220 °C

(-40 °F … 428) °F,

Stationary seat lock necessary.

Sliding velocity: vg = 20 m/s (66 ft/s)

Notes: The range of preesure,temperature and sliding velocity is depend on seals

Combination material

Rotary Face

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Tungsten carbide

Stationary Seat

Silicon carbide (RBSIC)

Tungsten carbide

Elastomer

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

PTFE Enwrap Viton

Bellows

Alloy C-276

Stainless Steel (SUS316)

AM350 Stainless Steel

Alloy 20

Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Mediums: Hot water, oil, liquid hydrocarbon, acid, alkali, solvents, paper pulp and other medium-and-low-viscosity content.

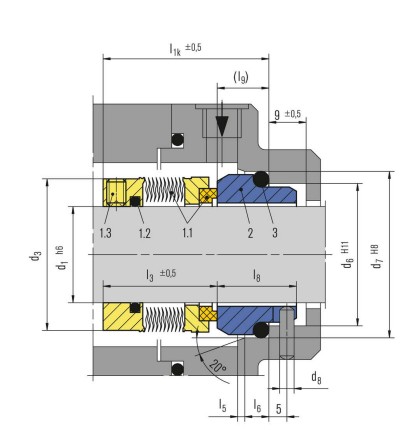

Item Part No. DIN 24250 Description

1.1 472/481 Seal face with bellows unit

1.2 412.1 O-Ring

1.3 904 Set screw

2 475 Seat (G9)

3 412.2 O-Ring

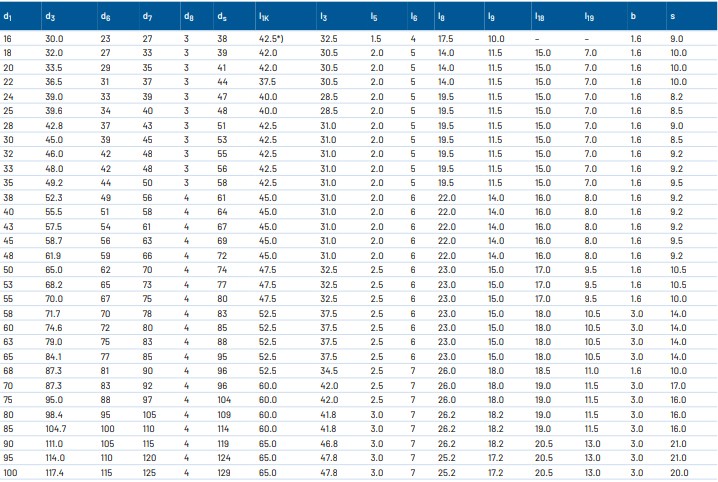

WMFL85N Dimension Data Sheet (mm)