WRO multiple spring and O-ring pusher mechanical seals Flowserve RO replacement

Features

• Single Seal

• Dual Seal available upon request

• Unbalanced

• Multi-spring

• Bi-directional

• Dynamic O-ring

Recommended applications

General Industries:

Pulp & Paper

Mining

Steel & Primary Metals

Food & Beverage

Corn Wet Milling & Ethanol

Other Industries

Chemicals:

Basic (Organic & Inorganic)

Specialty (Fine & Consumer)

Biofuels

Pharmaceutical

Water:

Water Management

Waste Water

Agriculture & Irrigation

Flood Control System

Power:

Nuclear

Conventional Steam

Geothermal

Combined Cycle

Concentrated Solar Power (CSP)

Biomass & MSW

Operating range

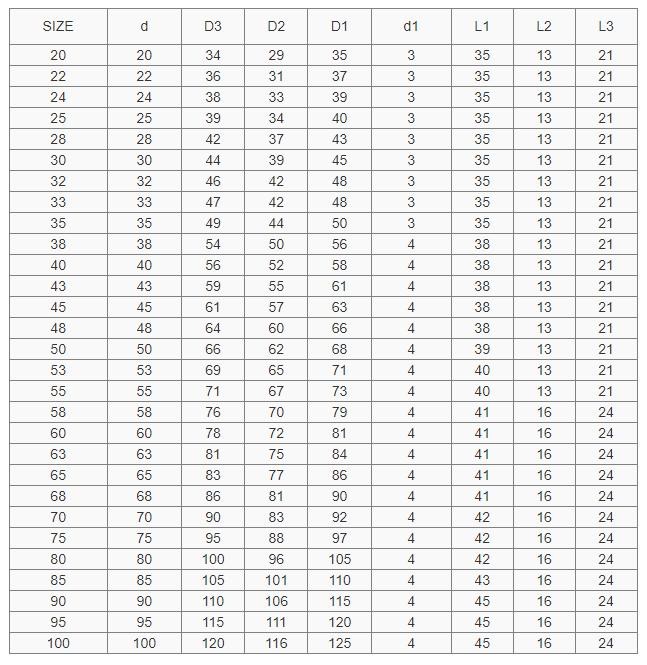

Shaft diameter: d1=20…100mm

Pressure: p=0…1.2Mpa(174psi)

Temperature: t = -20 °C …200 °C(-4°F to 392°F)

Sliding velocity: Vg≤25m/s(82ft/m)

Notes: The range of pressure, temperature and sliding velocity is depend on seals combination materials

Combination material

Rotary Face

Silicon carbide (RBSIC)

Tungsten carbide

Cr-Ni-Mo Sreel (SUS316)

Stationary Seat

Silicon carbide (RBSIC)

Carbon graphite resin impregnated

Auxiliary Seal

Fluorocarbon-Rubber (Viton)

Ethylene-Propylene-Diene (EPDM)

PTFE Coated VITON

PTFE T

Spring

Stainless Steel (SUS304)

Stainless Steel (SUS316)

Metal Parts

Stainless Steel (SUS304)

Stainless Steel (SUS316)

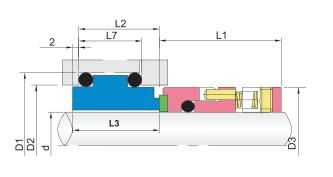

WRO Data Sheet of Dimension (inches)

Why choose us

Customization

We have a strong R&D team, and we can develop and produce products according to the drawings or samples the customers offered

Low Cost

We are production factory, compared with the trading company, we has great advantages

High Quality

Strict material control and perfect testing equipment to ensure product quality

Multiformity

Products include slurry pump mechanical seal, agitator mechanical seal, paper industry mechanical seal, dyeing machine mechanical seal etc.

Good Service

We focus on developing high-quality products for top-end markets. Our products are in line with international standards