Component mechanical seals are modular sealing systems made from separate rotating and stationary elements that are assembled during installation. Using hard-face materials like silicon carbide or tungsten carbide paired with chemical-resistant elastomers, they provide reliable sealing performance across varying pressures, temperatures, and media. Their replaceable, independent components make maintenance straightforward while ensuring stable operation.

proven manufacturing capability

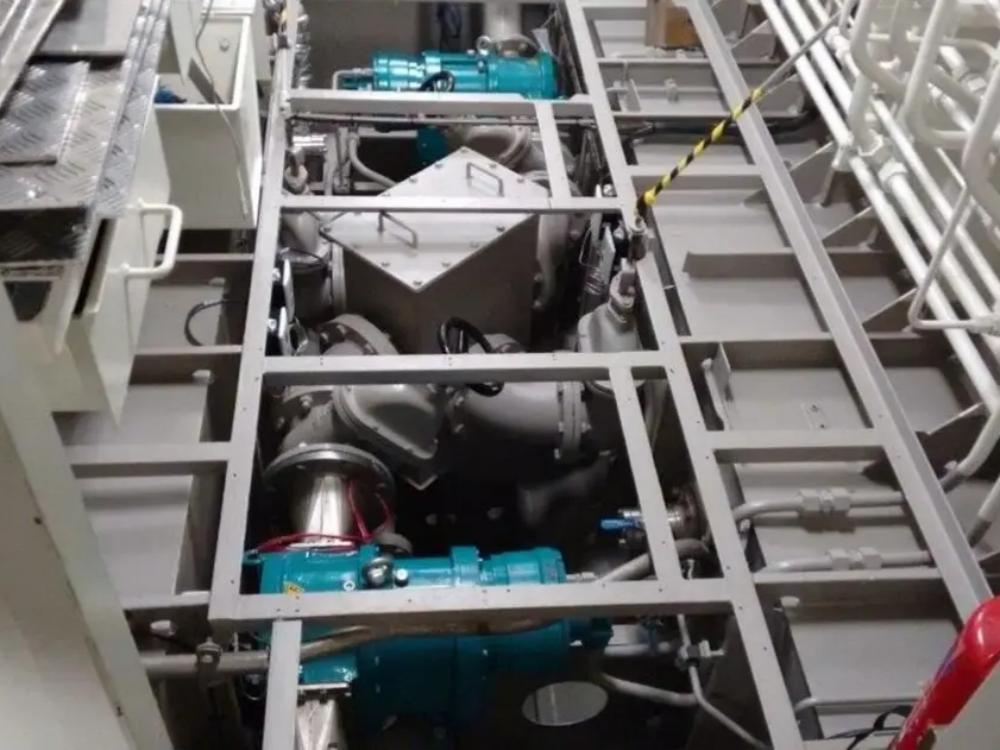

With registrations in 30+ countries and a 3,800㎡ production facility staffed by 40+ professionals, Victor delivers reliable, precision-engineered mechanical seals tailored for demanding marine applications.

quality assurance through strict validation

Every mechanical seal is fully inspected—100% dimensional checks and pressure-leak tests—ensuring stable sealing performance and consistency across all batches.

comprehensive pump seal solutions

Victor offers complete product lines designed to international standards (DIN24960, EN12756, ISO3069). OEM customization and a full range of SiC, TC, ceramic, and carbon spare parts support varied working conditions.

Victor’s component mechanical seals covers five major types, each designed to meet different operating conditions and industry requirements. With high-quality materials and precise manufacturing, Victor provides durable sealing solutions for industrial, commercial, and process pumps.

Single spring mechanical seals use a single, heavy-duty coil to maintain consistent face pressure, even with shaft runout or vibration. Their simple structure ensures dependable sealing in clean or slightly contaminated media. Victor supplies single spring seals optimized for stable, economical performance in general industrial pumps.

Multi spring mechanical seals utilize multiple small springs to distribute axial load evenly across the seal faces. This design delivers excellent thermal stability and consistent sealing under fluctuating pressure or temperature. Victor’s multi spring seals are engineered for precision, making them ideal for demanding chemical or process applications.

Wave spring mechanical seals rely on a compact, flat-wave spring that provides uniform force while keeping the seal design lightweight and space-efficient. They perform well where installation space is limited or where smooth axial movement is essential. Victor produces wave spring seals that offer reliable sealing with reduced spring fatigue.

Elastomer bellow mechanical seals use flexible rubber bellows to accommodate shaft misalignment and eliminate the need for a separate secondary seal. They are well-suited for low-pressure or general-purpose pumps handling clean liquids. Victor designs elastomer bellow seals for easy installation and steady sealing performance.

Metal bellow mechanical seals employ welded metal bellows that provide excellent flexibility, corrosion resistance, and high-temperature capability. They avoid sticking or wear in thermal cycling conditions. Victor manufactures metal bellow seals built for long life in high-temperature, aggressive chemical, or vacuum-level applications.

Victor’s component seals are engineered for versatility, allowing them to perform reliably across a wide range of pumping applications. Whether the system handles clean water, lubricating oils, high-speed centrifugal flow, or abrasive slurries, our seal configurations can be matched to the specific operating conditions for stable, long-term performance.

Component mechanical seals are widely used in water pumps due to their flexible configurations and stable sealing behavior. For clean or lightly contaminated water systems, single spring and elastomer bellow designs provide reliable sealing with simple installation. In high-flow municipal or industrial water pumps, multi spring configurations offer more uniform face loading, ensuring consistent performance across varying pressures and temperatures.

Oil pump environments often involve lubricating media and higher operating temperatures. Metal bellow and multi spring seals are commonly preferred because they maintain face stability under thermal expansion and resist deformation caused by viscosity changes. For compact oil pump layouts, wave spring designs help reduce axial space while maintaining effective sealing under fluctuating loads.

Centrifugal pumps operate at higher shaft speeds and may experience vibration or misalignment. Single spring seals provide stable face tracking, while multi spring and wave spring structures enhance balance and allow for precise load distribution at higher RPM. Where chemical compatibility is critical, elastomer bellow seals offer corrosion resistance and installation flexibility.

Slurry media introduce abrasives and irregular pressure conditions, requiring seals with strong wear resistance and robust load capability. Metal bellow and multi spring mechanical seals are often selected due to their ability to maintain uniform seal face pressure under abrasive attack. For low-pressure slurry transfer systems, reinforced elastomer bellow designs provide a cost-effective option while accommodating shaft movement caused by solids content.

Before choosing the right sealing solution, it’s important to understand how component mechanical seals differ from cartridge mechanical seals. Victor offers both types, enabling users to select the most suitable option based on installation practices, maintenance preferences, and operating conditions.

Component mechanical seals consist of individual parts that are assembled during installation, which gives users greater flexibility in materials, face combinations, and spare-parts replacement. This modular design makes them cost-effective and suitable for pumps where customization or frequent part-level maintenance is preferred. However, because compression settings and face alignment must be adjusted on site, installation quality has a higher impact on sealing performance, making them ideal for facilities with experienced technicians and standard operating conditions.

Cartridge mechanical seals are delivered as factory-assembled units with pre-set compression, pre-aligned faces, and integrated hardware. This plug-and-play design minimizes installation errors, shortens maintenance time, and supports more consistent sealing performance, especially in demanding or high-duty service. Although the upfront cost is typically higher and component-level customization is more limited, cartridge seals offer strong advantages for applications where reliability, repeatability, and quick change-outs are critical.

Installing a component mechanical seal requires particular attention because the seal is assembled directly on the pump shaft rather than supplied as a pre-set unit. Proper handling and alignment are essential to ensure reliable sealing performance. Victor experts recommend following the practices below to ensure a correct and trouble-free installation.

Component seals include multiple separate parts—rotary unit, stationary seat, secondary seals, and springs. Before starting, confirm every component is clean, undamaged, and corresponds to the correct size and material for the pump. Check that O-rings, bellows, or gaskets match the required chemical compatibility.

The stationary seat must be fitted squarely into the seal chamber to ensure proper face alignment. Use clean, non-metallic tools to press the seat in place without chipping or scratching the lapped face. Any debris or misalignment underneath the seat can create face runout, leading to immediate leakage during startup.

Slide the rotary components onto the shaft carefully and in the correct order to avoid overstressing elastomers. Only lubricate rubber elements lightly—never the sealing faces. Confirm springs, drive pins, or set screws are positioned correctly so the rotary unit maintains uniform closing force when the pump begins to operate.

Component mechanical seals require manual axial positioning, making this step critical to performance. Position the rotary assembly to the specified installation dimension and tighten the set screws evenly. Incorrect setting can produce excessive face load, insufficient closing pressure, or accelerated wear once the pump starts running.

After assembly, verify the shaft rotates smoothly and the seal faces remain uncontaminated. Fill the pump with liquid before starting to prevent dry running. Start the system gradually and monitor leakage, temperature, and vibration. Stable operation during the initial moments helps the seal settle properly.

Acquire all kinds of knowledge from professional China pump seal manufacturer

Double-layer sealing is a road surface treatment method. It uses two layers of asphalt and aggregate. This method helps protect roads from water and traffic damage. Engineers choose this sealing method for busy roads because it is more durable than other methods. Understanding different types of mechanical seals is crucial for many industries.

Many water pump failures are caused by problems with the seals. Studies show that approximately 70% of water pump failures are caused by mechanical seal issues. Leaks are often noticed due to dry running, overheating damage, or misalignment of the seal ring. Technicians must follow safety rules and use the correct

When the water pump seal fails, coolant will leak. The engine may overheat rapidly. Early detection can prevent costly repairs. Car owners should act quickly and choose high-quality mechanical seals, such as Victor mechanical seals, to ensure vehicle safety. Key Takeaways What Happens When a Water Pump Seal Fails Coolant Leakage and Loss

The biggest difference between Type 1 and Type 2 mechanical seals lies in their manufacturing process and sealing principle. Victor’s seals are robust and durable, effectively preventing leaks in pumps and machines. Their products are of exceptional quality, which is why many companies trust Victor when they need durable and reliable products. Key Takeaways

Common signs include:

Visible leakage around the seal area, drip by drip or continuous weeping.

Excessive heat or noise, often caused by insufficient lubrication or face damage.

Vibration or shaft wobbling, which accelerates face wear and leads to leakage.

Process fluid contamination, such as mixing of water and oil, indicating a compromised sealing interface.

Seal chamber corrosion or deposits, showing chemical attack or dry-running conditions.

If any of these symptoms appear, the seal should be inspected immediately to prevent further pump damage or unplanned downtime.

To measure a component mechanical seal accurately, focus on the three critical dimensions used for selection and replacement:

Shaft Size (Inside Diameter)

Measure the actual diameter of the pump shaft or sleeve where the rotating seal is installed. This determines the seal ID.

Seal Seat / Bore Size (Outside Diameter)

Measure the inside diameter of the pump housing or gland where the stationary seat fits. This defines the required OD of the seat.

Working Length (Seal Height)

Measure the axial distance from the gland to the shaft shoulder or impeller hub. This ensures the assembled seal has the correct compression and won’t overload the faces.

For accurate replacement, verify the material, drive style, and face combination as well. Even small deviations can lead to leakage, improper compression, or premature wear.

To select the right component mechanical seal, start by matching the shaft size and seal chamber dimensions of your pump. Then consider the fluid type, temperature, pressure, and abrasiveness, which determine the correct face materials and elastomers. You should also review the pump’s operating speed and lubrication/flush conditions to ensure stable performance.

If you’re unsure, Victor can recommend the proper seal configuration based on your pump model and working conditions, helping you avoid leakage issues and improve service life.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

About Victor

Contact Victor