Elastomer bellow mechanical seals are molded, flexible sealing units made from rubber-based materials. The bellows provides both sealing and self-alignment, allowing the seal faces to maintain stable contact without additional springs. This simple, compact design makes elastomer bellow seals a cost-effective choice for general-purpose pumps operating in low-pressure, non-corrosive, and moderate-temperature conditions.

precision engineering & reliable seal materials

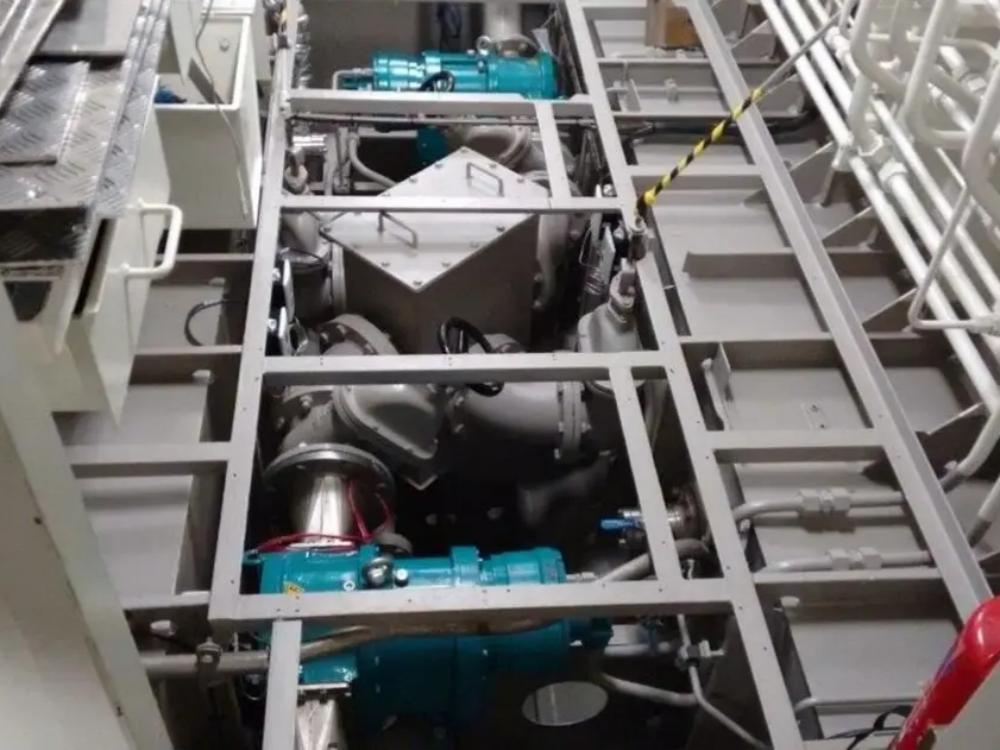

Our mechanical seals are manufactured using advanced CNC machining to achieve strict tolerances and stable performance. Each metal and elastomer component is made from high-quality materials, ensuring durability and long service life in demanding pump applications.

customized mechanical seal solutions for pumps

We develop tailor-made seal designs to match specific pump conditions and operating environments. Victor supplies OEM-equivalent mechanical seals for well-known pump brands, including IMO, Grundfos, Alfa Laval, Flygt, ABS, Lowara, Allweiler, KRAL, Emu, APV, Fristam and more.

fast technical support & after-sales service

Our engineering team provides quick assistance for installation, troubleshooting, and seal selection. This rapid response helps reduce equipment downtime and keeps your pumping systems running smoothly.

An elastomer bellow mechanical seal operates by relying on the flexibility of the bellows to maintain continuous contact between the stationary and rotating sealing faces. The bellows itself functions like a built-in spring, applying a consistent closing force that keeps the sealing faces pressed together, ensuring a leak-free interface. As the shaft rotates, a thin layer of fluid from the system forms between the sealing faces, creating a lubricating film that reduces friction, dissipates heat, and prevents excessive wear. The elastic nature of the bellows allows the seal to automatically adjust for axial movement, minor shaft misalignment, and gradual wear of the sealing surfaces. This self-compensating behavior ensures stable performance over time, without the need for manual adjustment or external springs. By absorbing small vibrations and accommodating dynamic changes in shaft position, the bellows minimizes stress on the sealing faces, reducing the risk of leakage or premature failure.

Overall, the elastomer bellow design allows the seal to maintain continuous, reliable contact under varying operational conditions, providing smooth rotation and effective sealing performance throughout its service life.

Elastomer bellow seals are designed to absorb both breakout and running torque through features like drive bands and interlocking tangs. This ensures that the bellows are not overstressed, preventing slippage and protecting the shaft and sleeve from wear or scoring. The positive drive design allows the seal to maintain stable contact during upset conditions.

The bellows’ elastic construction allows for automatic adjustment to compensate for abnormal shaft-end play, run-out, and primary ring wear. Uniform spring pressure provided by the bellows accommodates axial and radial shaft movement, ensuring the sealing faces remain in proper alignment. This self-compensating capability reduces maintenance requirements.

Elastomer bellow mechanical seals feature a unitized, cartridge-style construction with a single, non-clogging coil spring. This design prevents folding or creasing under pressure and allows the seal to operate reliably even with fluids containing solids. The compact, short axial length makes installation and replacement fast and straightforward.

Victor’s elastomer bellow mechanical seals are engineered to perform reliably across a wide range of pump and general industrial applications. Every unit undergoes precise dimensional verification and leak-proof testing, supported by continuous sampling control throughout manufacturing.

Elastomer bellow mechanical seals are widely used in centrifugal pumps because the flexible bellows can absorb minor shaft misalignment and axial movement. Their simple, single-unit structure ensures reliable sealing for water, light chemicals, and general industrial fluids, making them ideal for HVAC systems, circulation pumps, and industrial water supply applications.

In slurry pumps that handle fluids containing sand, silt, or fine particles, elastomer bellows provide stable sealing performance thanks to their ability to tolerate vibration and shaft movement. Although typically used in low-to-medium concentration slurries, they offer good abrasion resistance and chemical compatibility, making them suitable for mining, construction, and wastewater pretreatment systems.

Submersible pumps require seals that operate reliably underwater and resist contamination. Elastomer bellow mechanical seals are commonly used due to their compact design and reduced clogging risk. The bellows compensate for shaft deflection while maintaining a consistent closing force, making them suitable for sewage transfer, drainage, dewatering, and groundwater pumping.

In household and garden pumps—such as garden irrigation systems, pool pumps, shallow-well pumps, and small booster pumps—elastomer bellow seals offer an economical and easy-to-install solution. Their flexible structure allows stable performance in low-pressure and clean-water environments, making them ideal for residential and light-duty applications.

Victor uses carefully engineered material combinations for its elastomer bellow mechanical seals. Each seal can be configured with different face materials, seat options, elastomers, and metal components to match the fluid characteristics, temperature limits, and operating conditions of various pumps.

Carbon Graphite Resin Impregnated: Resin impregnation improves strength and reduces porosity, ensuring stable performance in clean or lightly contaminated media.

Antimony Impregnated Carbon: Provides higher hardness and improved thermal conductivity, suitable for applications with higher load or moderate abrasives.

Hot-Pressing Carbon / Full Carbon: Dense and wear-resistant, delivering long service life in high-temperature or chemically aggressive environments.

Silicon Carbide (SiC / RBSiC / SSIC): Extremely hard and corrosion-resistant, ideal for high-speed pumps and abrasive fluids.

Tungsten Carbide (TC): Very tough and impact-resistant, performing well in slurry or high-pressure applications.

Aluminium Oxide (Ceramic): Aluminium oxide provides good hardness and corrosion resistance, suitable for clean water and general-purpose sealing.

Silicon Carbide (SiC / RBSiC / SSIC): Silicon carbide offers exceptional wear resistance and thermal shock stability for demanding industrial applications.

Tungsten Carbide (TC): Durable and abrasion-resistant, TC is ideal for slurry and high-pressure pumping conditions.

Carbon: Low friction and good emergency running capability, carbon suits for non-abrasive and moderate-temperature environments.

NBR (Nitrile-Butadiene Rubber): Resistant to oils, fuels, and many hydrocarbons, NBR offers reliable sealing performance in general industrial pumps. It provides good compression set resistance and maintains elasticity under moderate temperatures, making it suitable for oil-based fluids, lubricating systems, and standard water applications.

EPDM (Ethylene-Propylene-Diene Rubber): Highly resistant to hot water, steam, mild chemicals, and weathering, EPDM performs well in systems where water-based media or alkaline solutions are present. Its excellent flexibility and temperature stability make it ideal for HVAC pumps, circulation pumps, and applications requiring long-term sealing reliability without oil exposure.

FKM / Viton (Fluorocarbon Rubber): Designed for high temperature and chemically aggressive environments, FKM provides outstanding resistance to acids, solvents, fuels, and corrosive fluids. It maintains superior sealing integrity under thermal cycling and vacuum conditions, making it suitable for chemical processing pumps and harsh industrial applications where durability is critical.

HNBR: With improved mechanical strength and enhanced heat and ozone resistance compared to standard NBR, HNBR performs reliably in dynamic applications subject to fluctuating pressures or higher load. It is commonly used in pumps handling refrigerants, oils with additives, or process fluids where both flexibility and toughness are required.

304 Stainless Steel: Provides reliable corrosion resistance for standard water and light-chemical applications.

316 Stainless Steel: Improved chloride corrosion resistance, ideal for seawater, chemical processing, and harsh industrial conditions.

Acquire all kinds of knowledge from professional China pump mechanical seal manufacturer

Double-layer sealing is a road surface treatment method. It uses two layers of asphalt and aggregate. This method helps protect roads from water and traffic damage. Engineers choose this sealing method for busy roads because it is more durable than other methods. Understanding different types of mechanical seals is crucial for many industries.

Many water pump failures are caused by problems with the seals. Studies show that approximately 70% of water pump failures are caused by mechanical seal issues. Leaks are often noticed due to dry running, overheating damage, or misalignment of the seal ring. Technicians must follow safety rules and use the correct

When the water pump seal fails, coolant will leak. The engine may overheat rapidly. Early detection can prevent costly repairs. Car owners should act quickly and choose high-quality mechanical seals, such as Victor mechanical seals, to ensure vehicle safety. Key Takeaways What Happens When a Water Pump Seal Fails Coolant Leakage and Loss

The biggest difference between Type 1 and Type 2 mechanical seals lies in their manufacturing process and sealing principle. Victor’s seals are robust and durable, effectively preventing leaks in pumps and machines. Their products are of exceptional quality, which is why many companies trust Victor when they need durable and reliable products. Key Takeaways

Lightly lubricate the shaft, inner diameter of the rotary seal, counterbore, and outer diameter of the stationary seat. For Ethylene Propylene rubber, use only silicone lubricant.

Press the stationary seat firmly into the counterbore, ensuring it sits squarely with the polished side facing the rotary seal.

Slide the rotary seal along the shaft to contact the stationary seat fully and parallel; ensure the spring is correctly engaged.

If included, install the gland plate gasket to seal the gland plate to the seal chamber.

Check the sliding fit: release pressure on the gland plate and confirm the spring moves the seal forward. If not, relubricate and reinstall quickly to prevent the rubber from bonding to the shaft.

Reassemble the pump and tighten all screws and nuts evenly.

Flood the pump to check for leaks, then start the pump. Never operate the pump dry.

The lifespan of an elastomer bellow mechanical seal depends largely on how it’s used and maintained. Under normal operating conditions, most seals last about 1 to 3 years, but with proper care, they can often run 3 to 5 years or longer. Factors that affect longevity include the amount of vibration or shaft misalignment, the type of fluid being sealed, and the operating temperature. Regular inspection, cleaning, and lubrication can help prevent premature wear and keep the seal performing reliably throughout its service life.

To ensure long-lasting performance, regular maintenance of an elastomer bellow mechanical seal is essential. Periodically inspect the bellows, sealing faces, and O-rings for wear, cracks, or deformation, and replace any damaged components. Keep the sealing faces clean and free of debris to maintain the thin fluid film that provides lubrication. Avoid dry running, as this can quickly damage the seal surfaces, and always operate within the seal’s recommended temperature and pressure limits. Minimizing shaft vibration and ensuring proper alignment will reduce stress on the bellows and prevent premature failure. Regular checks and timely maintenance help extend service life and ensure reliable operation.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

About Victor

Contact Victor