A pump seal is a precision-engineered device designed to prevent fluid leakage where a pump shaft passes through a housing. It achieves this by using polished sealing faces positioned perpendicular to the shaft’s axis. This design creates a strong, consistent barrier against gases and liquids while allowing controlled sliding between the faces.

At Victor, we specialize in manufacturing high-quality pump mechanical seals that deliver reliable performance in demanding applications. With over 27 years of expertise, we offer the same high-quality replacement parts and OEM solutions as global brands such as EagleBurgmann, John Crane, Vulcan, AES and Flowserve.

Developed with a flexible rubber bellows, this seal type is perfect for water, oil, and other light-duty pumping applications. It is commonly used in domestic water systems, light industrial pumps, and agricultural irrigation. Victor’s elastomer bellows seals are easy to install, compatible with many pump models, and available in both standard and OEM designs—offering dependable sealing with a pricing advantage over major global brands.

Using a compact wave-shaped spring, these seals save space while providing uniform face loading, making them ideal for pumps with limited installation room. They are often applied in marine cooling pumps, compact process pumps, and small high-speed units. Victor’s wave spring seals are engineered for durability, corrosion resistance, and easy installation, giving you a cost-effective alternative without compromising quality or performance.

Developed with a flexible rubber bellows, this seal type is perfect for water, oil, and other light-duty pumping applications. It is commonly used in domestic water systems, light industrial pumps, and agricultural irrigation. Victor’s elastomer bellows seals are easy to install, compatible with many pump models, and available in both standard and OEM designs—offering dependable sealing with a pricing advantage over major global brands.

Compared with common pusher seals, metal bellows seals eliminate dynamic O-rings, preventing seal hang-up and extending service life. They are widely used in high-temperature, corrosive, or sticky fluid applications, such as boiler feedwater pumps, refinery pumps, and chemical processing pumps. Our metal bellows seals are built with premium alloys and advanced designs, ensuring reliable operation in extreme conditions.

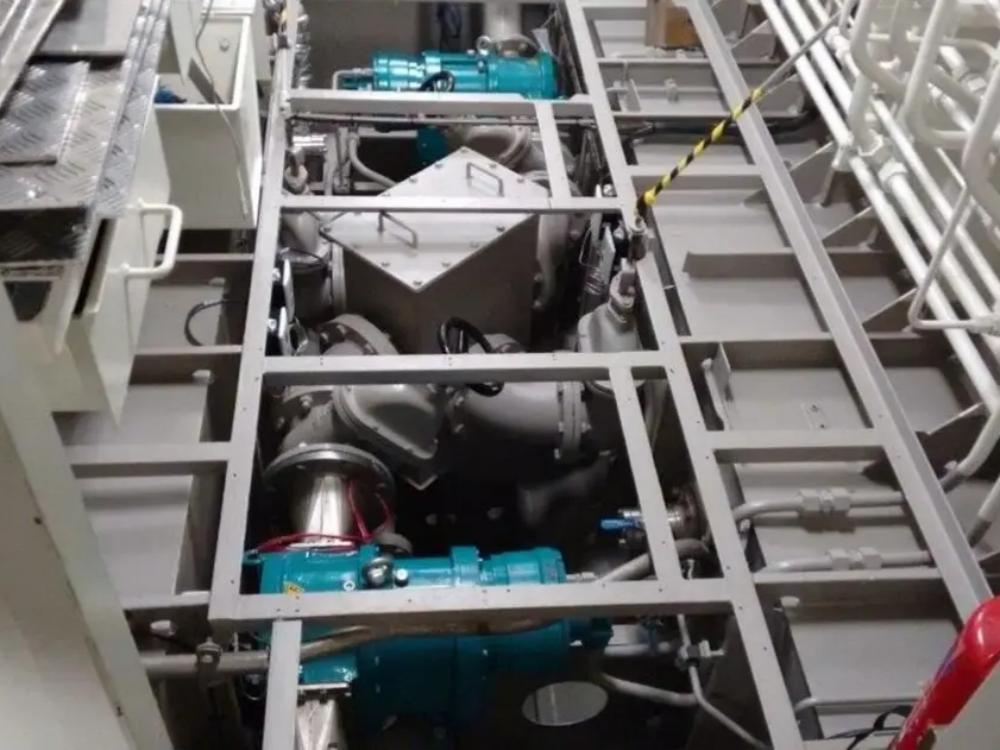

Cartridge seals are pre-assembled units that make installation quick and error-free, reducing downtime and maintenance costs. They are ideal for high-value systems like marine ballast pumps, process pumps, and critical industrial equipment. Our cartridge seals are designed for precise fit, high sealing performance, and easy replacement, providing a long-lasting solution with a strong cost-performance advantage over imported brands.

Featuring several small springs that evenly distribute pressure on the seal faces, these seals maintain performance in high-speed or high-pressure pumping applications. They are used in chemical transfer pumps, marine seawater pumps, and industrial cooling systems. Our multi spring seals are made with corrosion-resistant materials and precision-engineered faces to handle tough environments, offering OEM and replacement options at competitive prices.

Ningbo Victor

Victor is a leading Chinese manufacturer of marine pump mechanical seal, specializing in high-quality OEM alternatives to global brands like EagleBurgmann, John Crane, Vulcan, AES, and Flowserve. With 27 years of expertise, we ensure reliable performance, competitive pricing, and fast delivery—making us the smart choice for shipbuilders and pump manufacturers worldwide.

We are registered in 30+ countries, backed by a 3,800㎡ facility and 40+ skilled professionals. Our experience ensures precision-engineered seals for marine.

We offer 10% lower pricing than competitors without compromising quality. Our seals match the performance of EagleBurgmann, John Crane, and other leading brands.

With ample stock, we reduce lead times and ensure quick order fulfillment—keeping your operations running smoothly.

Every seal undergoes 100% dimensional inspection and pressure leakage testing before shipment. We also conduct sample checks during production for consistency.

Pump mechanical seal is essential to prevent leakage, maintain efficiency, and protect equipment. A proper installation process ensures reliable operation and extends seal life. The following are expert guidelines provided by Victor, designed to help you achieve correct and professional pump seal installation.

Before installation, ensure all tools and materials are ready, and the work area is clean. Inspect the pump shaft, seal chamber, and related surfaces for damage, dirt, or wear. Confirm the new seal matches the pump requirements and fluid type.

Shut down the pump safely, relieve system pressure, and drain any remaining fluid. Carefully remove the worn seal without scratching the shaft or housing. Clean all contact surfaces thoroughly to provide a smooth base for the new seal.

Handle seal parts with care to avoid contamination or scratches. Lubricate elastomers lightly and place seal faces correctly on the shaft. Align the gland and tighten fasteners evenly to ensure proper positioning and face alignment.

After installation, rotate the shaft by hand to confirm smooth movement. Verify all bolts are tightened and flush or cooling lines are connected. Start the pump slowly, monitor leakage, temperature, and vibration, and adjust if necessary.

Marine pumps, including seawater cooling pumps, ballast pumps, and fire-fighting pumps, require mechanical seals that resist corrosion, saltwater damage, and constant operation under harsh conditions. Victor recommends metal bellow mechanical seals and multi spring mechanical seals for these applications because of their corrosion resistance and ability to handle variable pressures.

Chemical pumps often handle aggressive, corrosive, or hazardous fluids that demand seals made of chemically resistant materials. Elastomer bellow mechanical seals and cartridge mechanical seals are ideal here, as they provide excellent chemical compatibility and simplify maintenance. Victor’s seals are designed to withstand harsh chemicals while preventing leakage and minimizing downtime.

In oil and gas applications, pumps must function reliably under high pressure and temperature, often dealing with hydrocarbons and other demanding fluids. Victor advises multi spring mechanical seals and metal bellow mechanical seals for their durability, ability to handle high pressures, and resistance to aggressive fluids. These seals meet stringent industry standards and provide safety in critical processes.

Water treatment plants and municipal water supply systems use pumps that require seals offering long-lasting reliability and minimal maintenance. Single spring mechanical seals and elastomer bellow mechanical seals are commonly recommended for their simplicity and cost-effectiveness in handling clean or treated water. Victor’s seals help reduce downtime and operational costs in these applications.

Across industries such as power generation, mining, and manufacturing, pumps handle various fluids, including abrasive and slurry mixtures. We suggest cartridge mechanical seals and metal bellow mechanical seals because we supplies seals made with wear-resistant materials to handle tough fluids, extending pump life and maintaining consistent operation.

Acquire all kinds of knowledge from professional China pump seal manufacturer

Double-layer sealing is a road surface treatment method. It uses two layers of asphalt and aggregate. This method helps protect roads from water and traffic damage. Engineers choose this sealing method for busy roads because it is more durable than other methods. Understanding different types of mechanical seals is crucial for many industries.

Many water pump failures are caused by problems with the seals. Studies show that approximately 70% of water pump failures are caused by mechanical seal issues. Leaks are often noticed due to dry running, overheating damage, or misalignment of the seal ring. Technicians must follow safety rules and use the correct

When the water pump seal fails, coolant will leak. The engine may overheat rapidly. Early detection can prevent costly repairs. Car owners should act quickly and choose high-quality mechanical seals, such as Victor mechanical seals, to ensure vehicle safety. Key Takeaways What Happens When a Water Pump Seal Fails Coolant Leakage and Loss

The biggest difference between Type 1 and Type 2 mechanical seals lies in their manufacturing process and sealing principle. Victor’s seals are robust and durable, effectively preventing leaks in pumps and machines. Their products are of exceptional quality, which is why many companies trust Victor when they need durable and reliable products. Key Takeaways

Fluid Characteristics

Corrosive or abrasive fluids can damage seal faces. We select materials like silicon carbide to resist wear. Precision polishing reduces friction, extending service life and keeping performance stable in harsh fluid environments.

Operating Pressure

High pressure increases stress on sealing faces. We use balanced seal designs and reinforced metal parts to handle pressure safely. This prevents overheating, distortion, and early wear during continuous high-pressure operation.

Operating Temperature

Extreme heat or cold affects material properties. We choose heat-resistant metals, high-grade elastomers, and expansion-tolerant designs. These measures ensure the seal keeps its shape and function under fluctuating temperature conditions.

Shaft Speed and Movement

Fast rotation generates heat and vibration. We design seals with optimized face geometry and high-lubricity materials to reduce friction. Strict tolerance control keeps alignment accurate, avoiding uneven wear and leaks.

Environmental and Safety Requirements

Hazardous fluids require zero leakage. We provide double seal systems and pressurized barrier fluids for maximum safety. Each unit is tested for leakage prevention before shipment.

Prepare the Work Area

Shut down the pump and disconnect all power sources. Drain the fluid from the pump. Clean the workbench and gather all tools, including seal installation tools, lubricants, and safety equipment.

Remove the Old Seal

Disassemble the pump housing according to the manual. Carefully remove the worn seal from the shaft or gland. Avoid scratching the shaft or housing, as even small damage can cause future leaks.

Inspect and Clean Components

Check the shaft, sleeve, and seal chamber for wear, scoring, or corrosion. Replace damaged parts. Thoroughly clean all contact surfaces to ensure the new seal sits properly.

Lubricate Seal Faces and O-Rings

Use a manufacturer-approved lubricant on elastomer parts and seal faces. This eases installation, prevents tearing of O-rings, and reduces initial friction when starting the pump.

Install the Stationary Part

Fit the stationary seat into the seal housing. Ensure it is clean, aligned, and pressed evenly. Avoid touching the seal face with bare fingers to prevent contamination.

Install the Rotating Part

Slide the rotating seal component onto the shaft or sleeve carefully. Ensure the set screws or drive lugs are positioned correctly. Do not force the part, as this can damage the sealing face.

Align and Secure

Check that the rotating and stationary faces are parallel and centered. Tighten the set screws or retaining hardware evenly. Follow the torque specifications given by the seal manufacturer.

Reassemble the Pump

Put the pump back together, ensuring all gaskets and fasteners are correctly placed. Rotate the shaft by hand to confirm smooth movement and no binding.

Test the Installation

Fill the pump with fluid and reconnect the power. Run the pump at low speed first, checking for leaks, noise, or vibration. Gradually increase to normal operating speed once the seal proves stable.

Monitor After Startup

Inspect the seal during the first hours of operation. Look for early signs of leakage or overheating. Adjust or recheck installation if needed.

1. Leakage at the Seal Faces

Cause: Seal faces are worn, scratched, or contaminated by dirt or crystallized fluid. Misalignment during installation can also cause uneven contact.

Solution: Inspect and replace damaged seal faces. Clean all parts before reassembly.

2. O-Ring or Gasket Leakage

Cause: O-rings are cut, swollen, or hardened due to chemical attack or excessive temperature.

Solution: Replace with correct material compatible with the pumped medium.

3. Excessive Wear on Shaft or Sleeve

Cause: Abrasive particles in the fluid, improper lubrication, or incorrect seal material.

Solution: Install a filter or flush system to reduce abrasives. Choose harder seal face materials such as silicon carbide.

4. Seal Overheating

Cause: Inadequate cooling, dry running, or excessive friction from poor alignment.

Solution: Check for proper lubrication and cooling flow. Avoid starting the pump without liquid.

5. Vibration or Noise

Cause: Misaligned pump, worn bearings, or cavitation. These issues can damage seal faces quickly.

Solution: Align the pump properly and inspect bearings. Ensure correct suction conditions.

6. Short Seal Life

Cause: Incorrect seal selection for pressure, temperature, or chemical compatibility.

Solution: Review application requirements and choose the right seal type. Victor offers OEM-equivalent and custom seals, ensuring the best match for marine pumps and other demanding applications.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

About Victor

Contact Victor